The Materials Development Laboratory develops new products characterized by unique technologies and also engages in research and development in next-generation fields.

Research and development activities in the field of inorganic research are focused primarily on titanates. Products such as TISMO and TERACESS, which are characterized by their excellent frictional stability, micro-level reinforcement and tribological characteristics are used in applications such as brake pads for automobiles. The same basic technologies are also being utilized in efforts to expand into other fields such as batteries and coatings. The laboratory is also developing functional composite materials that skillfully combine the characteristics of TISMO with various engineering plastics, expanding into a wide range of fields such as auto parts and smartphone components.

Features of the research institute

-

Development of materials

We also develop materials leveraging our basic technologies. Especially in the development of titanates for use in friction materials, we have a material development system in place as is proper for a leading company.

-

Application development

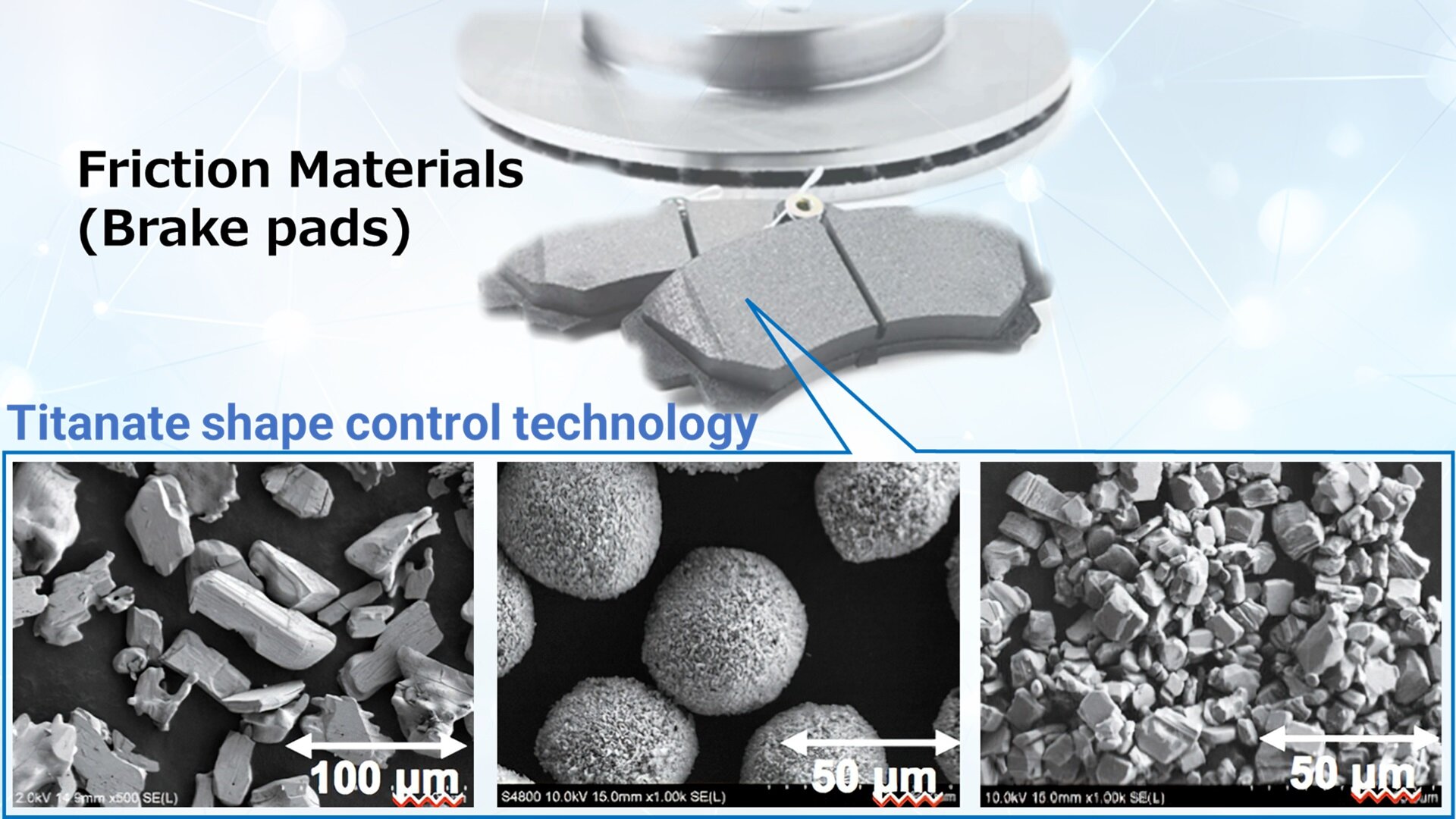

We research applications that maximize the happiness that TISMO, TERRACESS and DENTALL provide. Furthermore, we are actively developing new materials for new applications.

-

Development of composite materials

TISMO is very fine fibers and has excellent reinforcement properties. TISMO is combined with different kinds of plastics to make POTICON, an epoch-making composite material.

-

Development of molded products

Based on the extrusion processing technology we have developed to date, we advance the development of machining technologies to facilitate the proposal of differently shaped products. We will make a range of proposals to meet the diverse needs of customers.

Development case studies

-

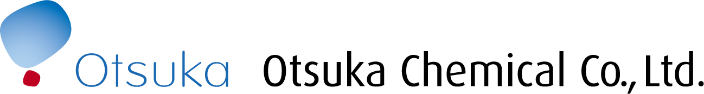

Development of titanates for friction materials

We engage in research and development focused primarily on titanates. Products such as TISMO and TERACESS, which are characterized by their excellent frictional stability, micro-level reinforcement and tribological characteristics are used in applications such as brake pads for automobiles. Additionally, we utilize other basic technologies such as those for control of shape or size, etc., and develop materials geared for specific purposes.

-

Application development maximizing material quality

We pursue the potential of many different product applications and propose ideas that enable happiness. Materials only have meaning when they perform functions in the the applications they are designed for. Regarding the applications we envision, we pursue happiness and conduct research to maximize the value of materials. Leveraging our basic technologies, we are also actively developing new materials for more applications.

-

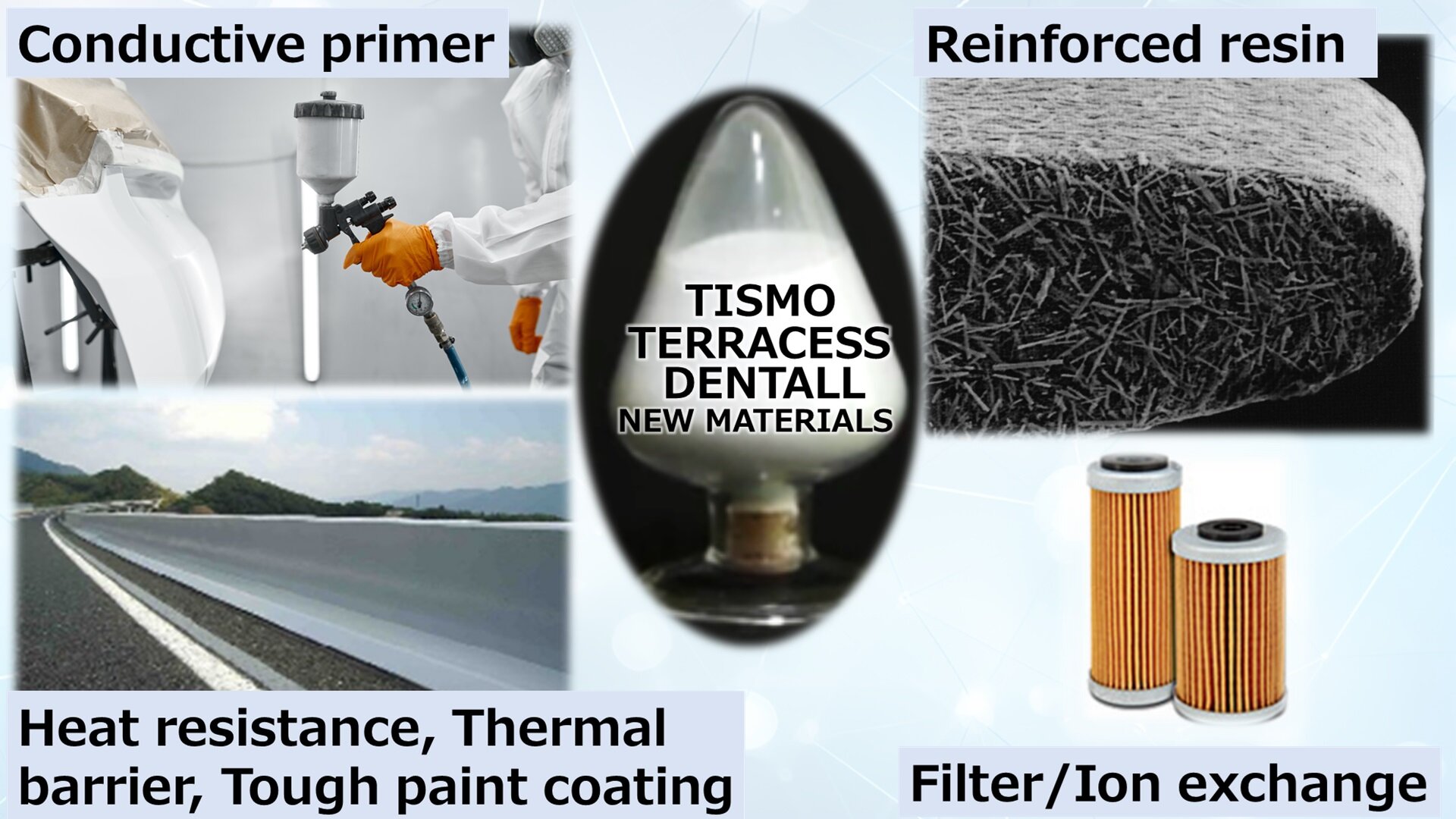

Development of POTICON, a composite material

POTICON is a kind of thermoplastic resin provided by Otsuka Chemical. The material contains TISMO, ultra-fine potassium titanate fibers, and is excellent for reinforcing molded products and increasing dimensional stability.

It has many different applications in areas such as drive components of automobiles, LED reflectors and camera module components. POTICON's recyclability is excellent, contributing to cost reduction.

-

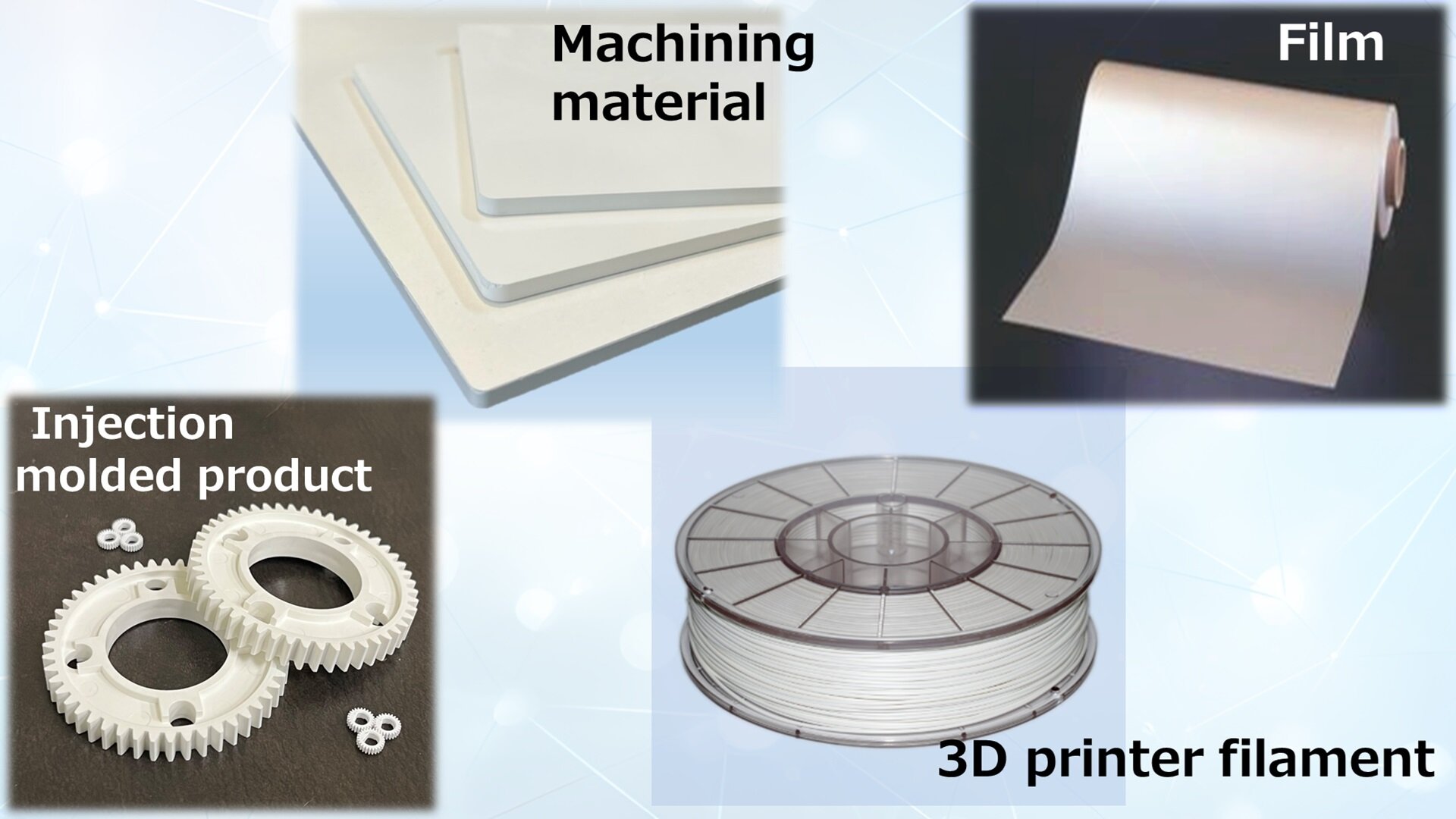

Application to resin compound materials and processed products

This has made it possible to manufacture components such as injection-molded products, plate materials, blocks, films and filaments for three-dimensional printers, in addition to materials. Injection-molded products are simulated in advance using fluid analysis. This allows dimensional standards and formability to be checked in advance and contributes to shortening the development period. Without having to make a mold, you can verify the feasibility of a shape to increase the value of a product. We exercise ingenuity in the composition of plate materials and blocks and in their production methods so that POTICON’s characteristic low aggressiveness can be utilized and it will be difficult to warp products during machining even when they have excellent free machinability. Films and tubes are resistant to bending and are characterized by secondary machining and adhesion to metal, leveraging POTICON's thin-wall molding, reinforcement and low linear expansion properties. Today, its applications are wider and include flexible printed circuits and multilayer boards. Filaments for three-dimensional printers contain reinforced fibers but allow molding using nozzle heads that are 0.2 millimeter in diameter or larger. While retaining their molding precision, they have sufficient strength, rigidity and surface smoothness and can be used as a jig without being modified. Also, the material is enables the design freedom that is unique to 3D printers.