TERPLUS block polymer pigment dispersant polymerized using the TERP method

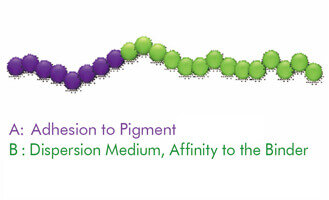

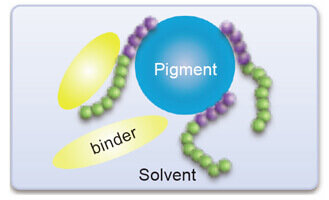

TERPLUS polymerized using the TERP method of living radical polymerization has a block polymer structure making it possible to control the arrangement of ingredients that affect pigment adsorption and dispersion medium affinity. It achieves strong adsorptivity at the pigment surface and steric stability through dispersion medium affinity. Consequently, it makes it possible to achieve both excellent dispersibility and dispersion stability.

Solution

As polymeric dispersants, TERPLUS dispersants improve the dispersion of organic and inorganic pigments and contribute to their long-term stability. Additionally, it is possible to equip products with many different applications with this feature, including pigment dispersion inks, paints and functional inks.

TERPLUS dispersants take on a block polymer structure which includes both the area for adsorption on the pigment surface and the area with an affinity for binders and other agents. You can design more effective dispersants by ensuring an optimal design for the target pigment and dispersion media.

Block Polymer Pigment Dispersant

Features

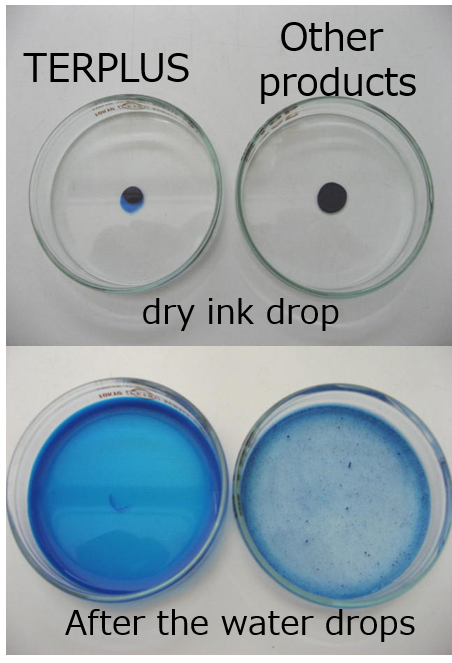

Dispersibility and dispersion stability

With the TERP method’s characteristics, including the diversity of the monomers that can be used, the control of molecular weight and block structure and other characteristics, TERPLUS dispersants take on a block polymer structure with a block for adsorption on the pigment surface and a block with an affinity to the dispersion media that exhibits steric and electrostatic repulsion. The dispersants maintain excellent dispersibility and good dispersion while inhibiting the reagglomeration of particles.

Reliably scaled up

The TERP method is highly reproducible from lab scale to industrial production scale where several tons of product are manufactured, and polymerization can be consistently controlled. We have a plant dedicated to this.

General Properties

Representing Grade Characteristics( Formulation for protective, JIS Z0237:2009)

| name | acid value (mgKOH/g) |

amine value (mgKOH/g) |

solvent | concentration (wt%) |

Applicable pigments |

Manufacturing Stage |

|||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Surface Properties |

metal | metal oxide |

carbon black |

Organic pigments |

|||||||

| Solvent- based |

TERPLUS D1200 (amine-based) |

- | 100-120 | PMA*1 | 50-60 | acidic | ○ | ○ | ○ | ○ | product |

| TERPLUS D1410B (amine-based) |

- | 75-90 | PMA*1 | 60-70 | acidic | ○ | ○ | ○ | ○ | pilot | |

| TERPLUS D1420 (quaternary salt system) |

- | 55-70 | PMA*1 | 50-60 | acidic | ○ | ○ | ○ | ○ | product | |

| TERPLUS D1460 (quaternary salt system) |

23-36 | 54-74 | PMA/MP*1 =5/5 |

35-45 | acidic | ○ | ○ | ○ | ○ | pilot | |

| TERPLUS MD1000 (acidic) |

75-95 | - | PMA/MP*1 =8/2 |

35-45 | basic | ○ | ○ | ○ | pilot | ||

| TERPLUS MD1100 (acidic) |

78-88 | - | PMA/MP*1 =8/2 |

35-45 | basic | ○ | ○ | ○ | pilot | ||

| Water- based |

TERPLUS AD1100B*2 (Hydrophilic - Hydrophilic type) |

80-120 (pre-neutralization) |

- | water (pH=5-9) |

25-35 | acidic | ○ | ○ | ○ | ○ | pilot |

| TERPLUS AD1200B*2 (Hydrophilic-hydrophobic type) |

90-110 (pre-neutralization) |

- | water (pH=7-10) |

20-30 | hydrophobic | ○ | ○ | ○ | pilot | ||

| TERPLUS FD1000 (Hydrophilic - Hydrophilic type) |

- | - | water (pH=4-7) |

40-50 | acidic | ○ | ○ | ○ | ○ | pilot | |

*1 PMA:Propylene glycol monomethyl ether acetate、 MP:Propylene glycol monomethyl ether *2 KOH neutralizer # The above are representative values, not guaranteed values.

Applications

Inkjet pigment dispersants

Inkjet ink must have different properties depending on its usage. The TERP method makes it possible to customize and optimize dispersants to tailor them to the various properties of the materials they will be used with.

Pigment dispersant for color filters