New Material Designed to Meet Global Needs

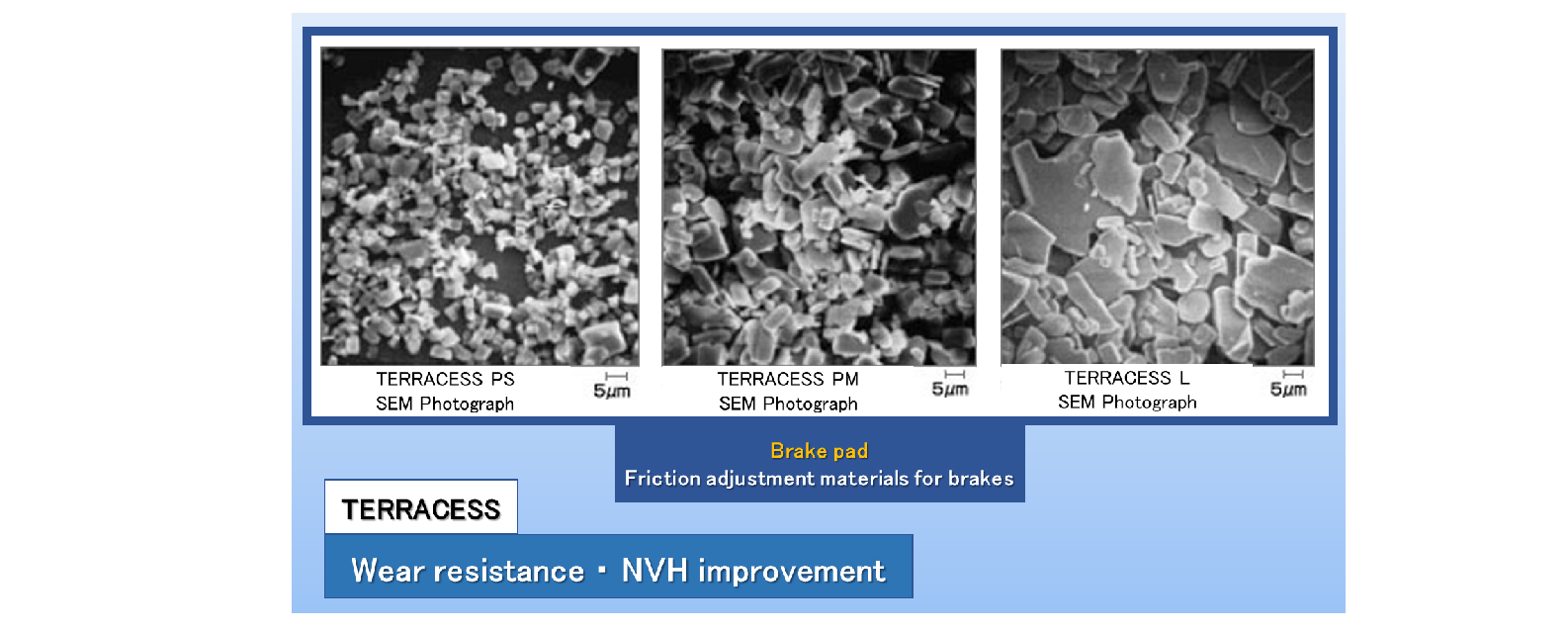

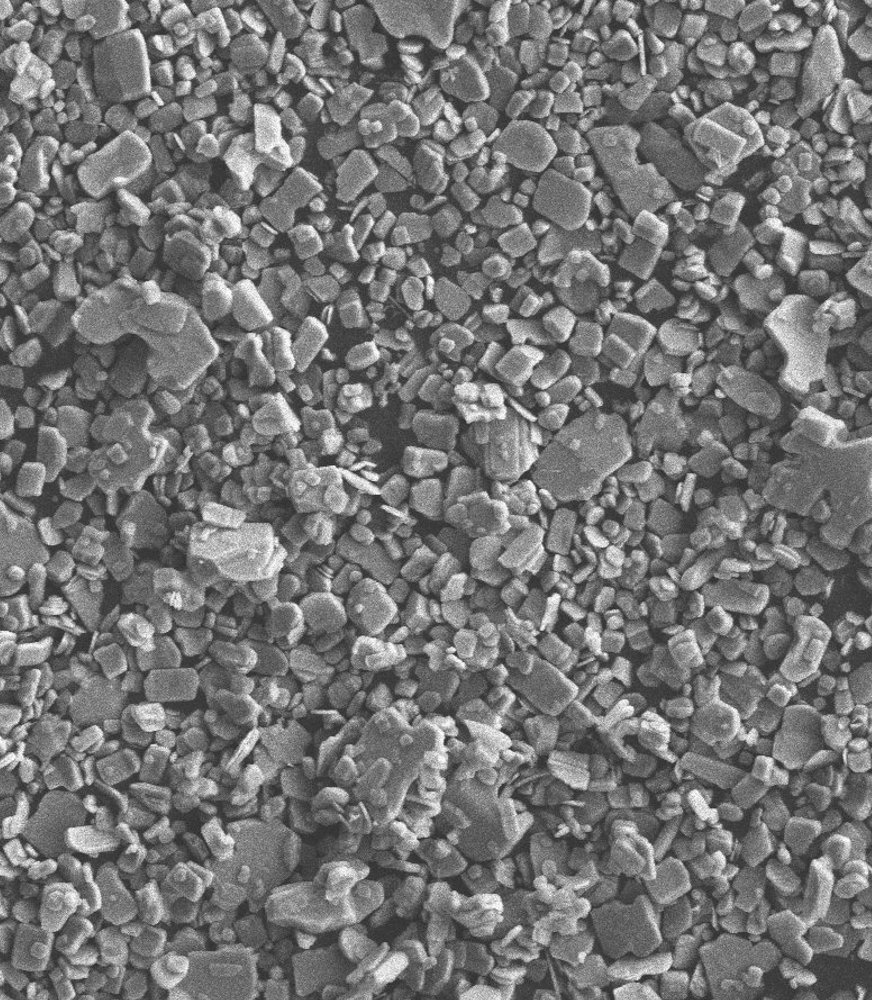

Thanks to our unique technology to control the shape and composition of titanates, Otsuka Chemical has developed a new series of compound materials. These titanates are primarily used in automotive brake pads as friction modifiers. We continue to expand usage globally as well as design cutting edge new grades offering improved friction characteristics.

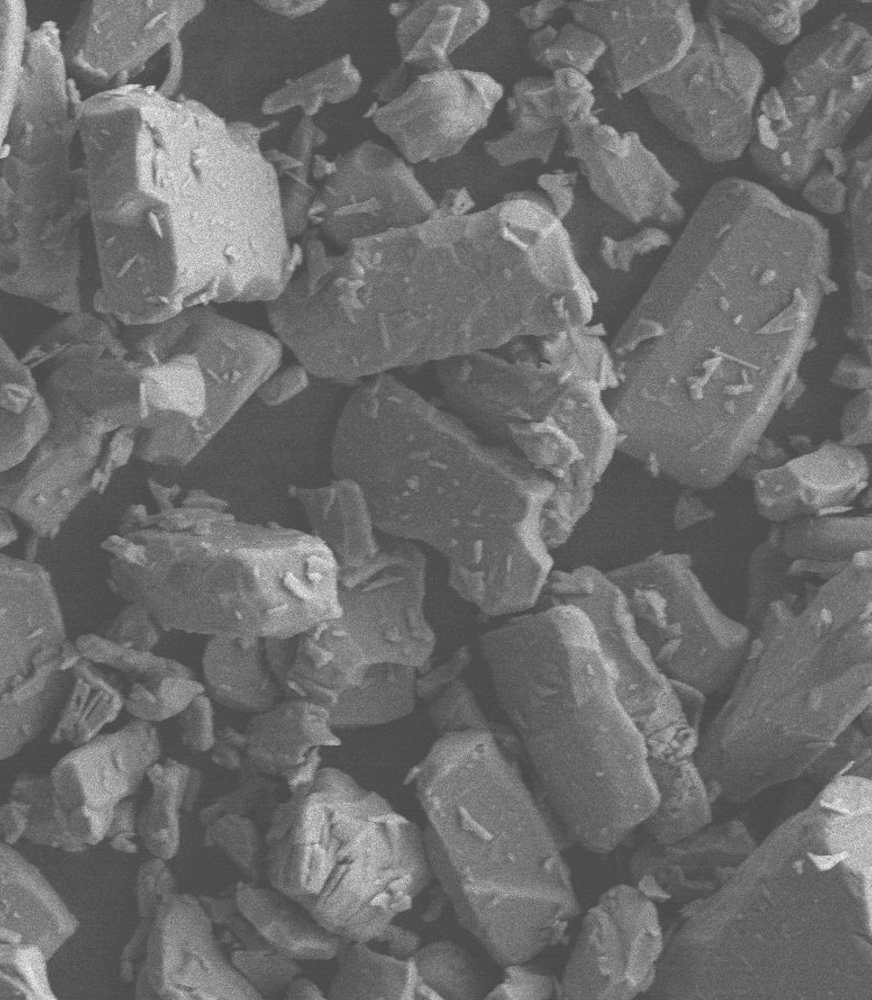

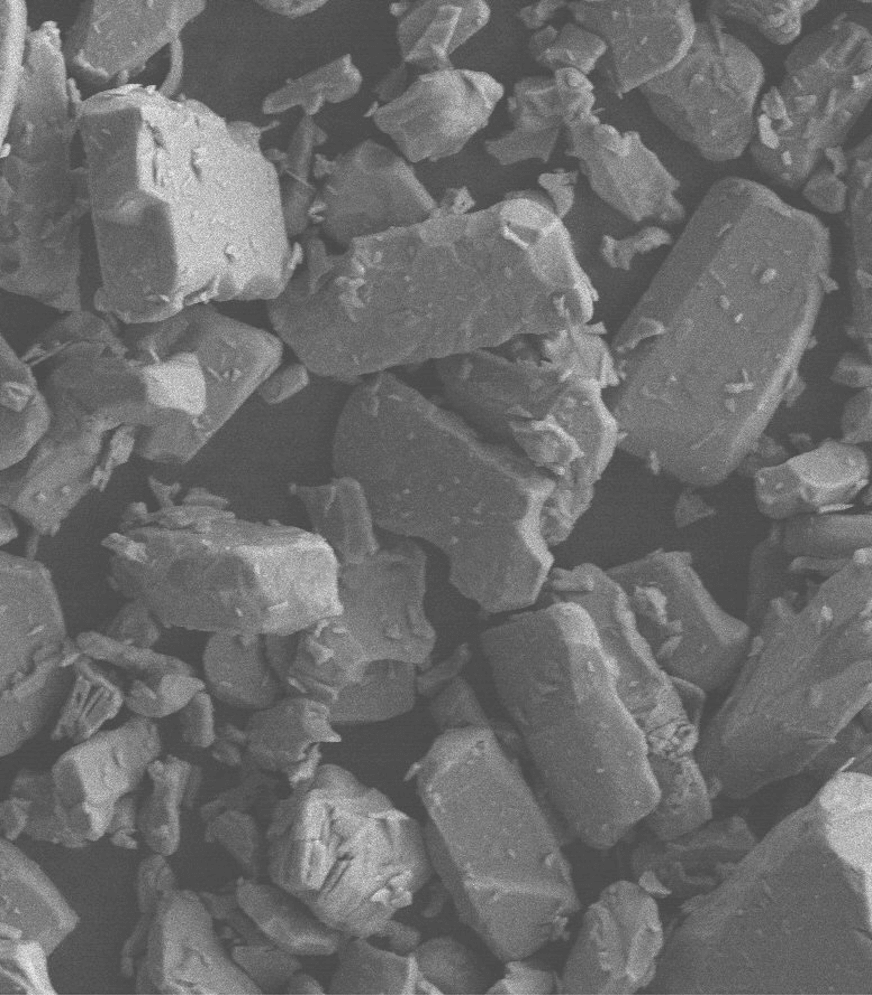

PS (x1000)

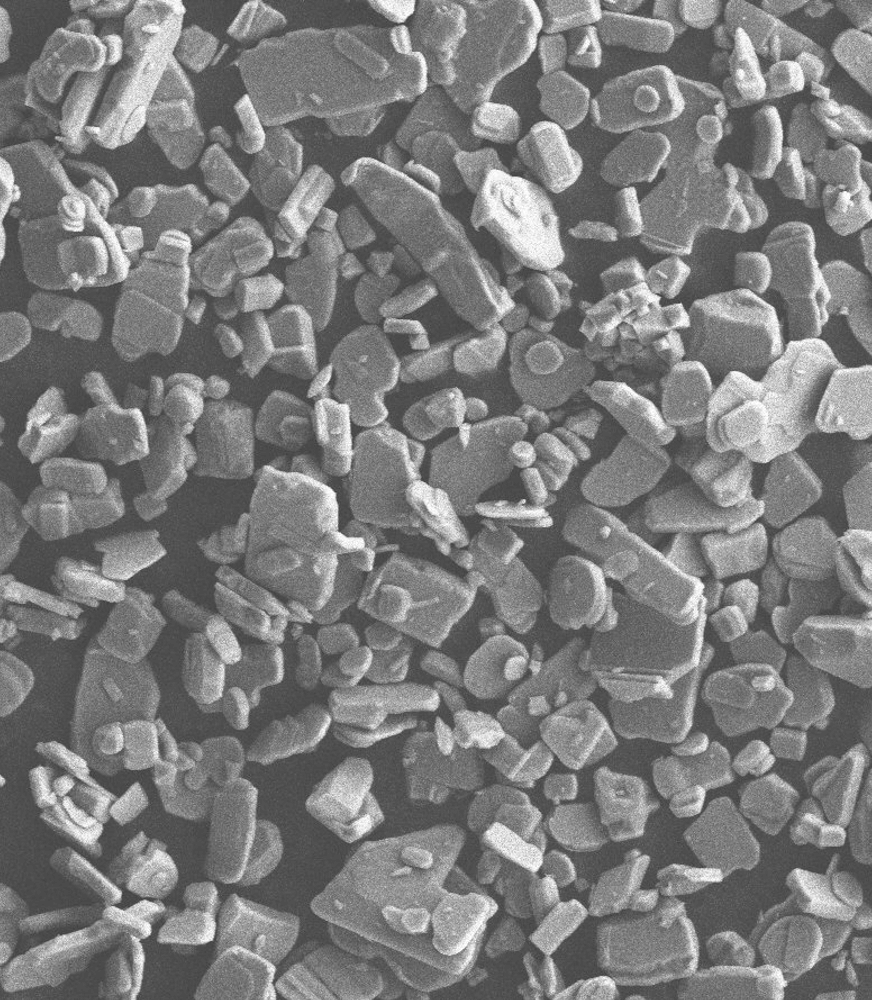

PM (x1000)

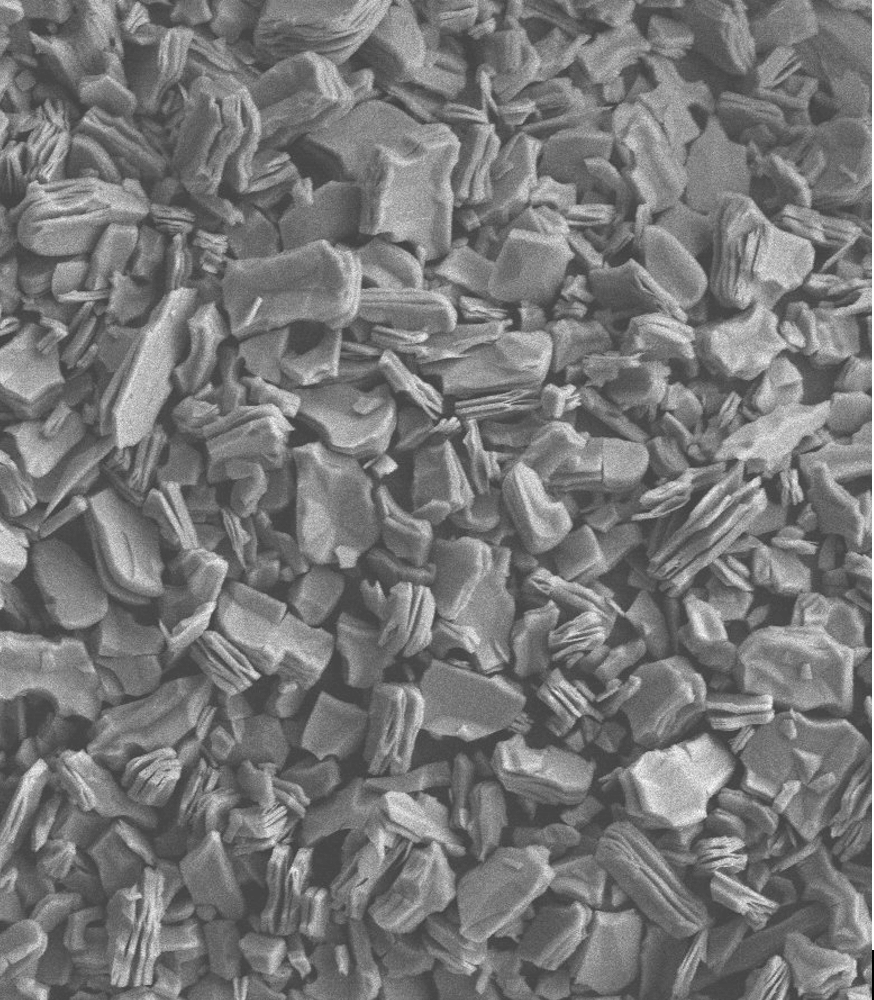

TF-S (x1000)

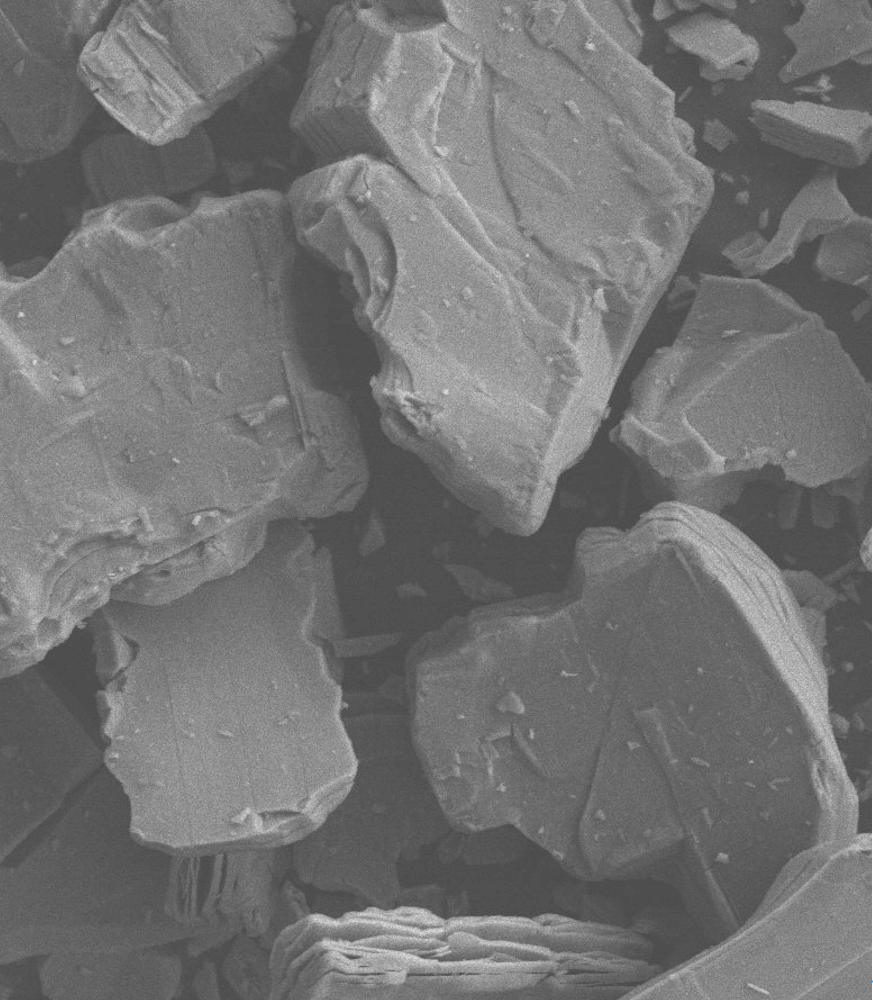

TF-L (x1000)

(x1000)

(x1000)

Advantages

TERRACESS, used as a friction modifier, can improve μ stability, wear resistance, fade property, and NVH.

These benefits are based on physical or mechanical properties caused by the titanates chemical structure and shape, and chemical reactions occurring at the friction interface caused by the chemical properties of the titanates.

By controlling these different properties we have created many grades with various characteristics. So we can always supply a suitable filler for our customer.

General Properties

| TERRACESS Grade | PM | PS | L | TF-L | TF-S | ||

|---|---|---|---|---|---|---|---|

| Chemical Name | Magnesium Potassium Titanium Oxide | Lithium Potassium Titanium Oxide | Potassium Titanium Oxide | ||||

| Crystal Structure | |||||||

| Median Size | μm | 5 ~ 10 | 2 ~ 6 | 10 ~ 35 | 15 ~ 45 | 3 ~ 11 | |

| pH | - | 10.0 ~ 11.5 | 10.0 ~ 11.5 | 10.0 ~ 11.5 | 8.5 ~ 10.5 | 8.5 ~ 10.5 | |

| Specific Surface Area | m²/g | 0.5 ~ 2.0 | 0.3 ~ 4.0 | 0.2 ~ 1.5 | 1.0 ~ 4.0 | 2.0 ~ 5.0 | |

| Aerated Bulk Density | g/cm³ | 0.3 ~ 0.7 | 0.25 ~ 0.75 | 0.5 ~ 0.9 | 0.3 ~ 1.3 | 0.2 ~ 0.8 | |

| Weight Loss on Drying | wt% | ≦ 0.7 | ≦ 0.7 | ≦ 0.7 | ≦ 0.7 | ≦ 0.7 | |

| Melting Point | °C | 1300 ~ 1350 | 1150 ~ 1200 | 1300 ~ 1350 | |||

| Particle Shape | Platelet | Platelet | Platelet | ||||

| Friction Characteristics | Good balance of μ level and wear | Outstanding low wear | Good μ level | ||||

*Note: The data is an approximate reference. *This drawing produced with ATOMS, by Shape Software.

Applications

- Friction modifier for automotive brake(Brake pad, Brake lining, Clutch etc.)