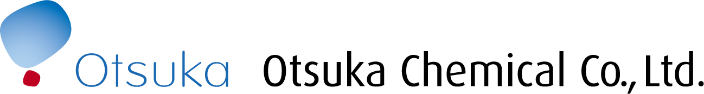

We developed a plate material with excellent micromachinability as well as the micro-level reinforcement and wear resistance that are characteristic properties POTICON. Because the demand for higher-density implementations of electronic components, semiconductor chips are shifting to using multiple pins and narrower pitches between pins while MLCCs are transitioning to an ultrasmall size. In this context, electronic component test jigs are increasingly expected to meet subtle and precise machining requirements. Using a POTICON plate material makes it easy to manufacture micromachined products at a high level.

What is a POTICON plate material?

Conventionally, POTICON pellets were sold for use in injection molding to make things such as gears and bearings where high precision and tribological characteristics are required. Recently, pellets have changed form, changing into a plate material that has been made available so users can experience its micromachinability, a new feature of the product. Going forward, our compounding technologies will be further utilized as we push forward with the development of a micromachinable POTICON plate material with added value in terms of, for example, low dielectric properties and the prevention of electrification.

Feature

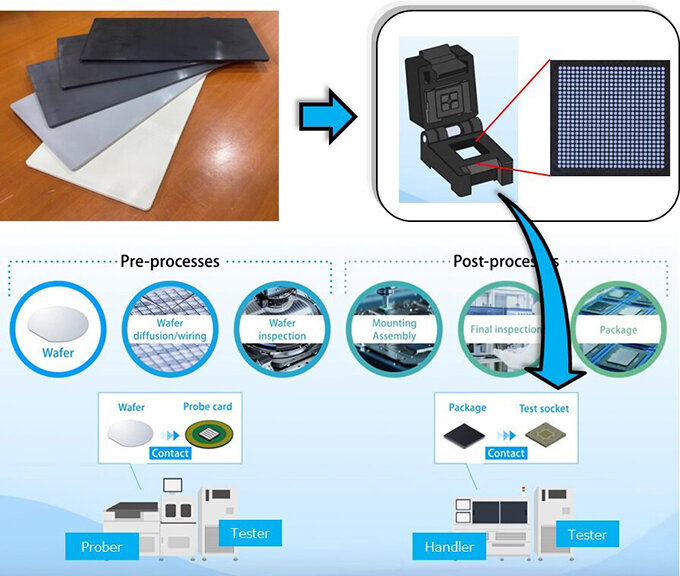

Micromachinability of POTICON plate materials

Using a micro-diameter drill makes it possible to make a round-hole machined product that is 20 micrometers in diameter with a wall thickness of three micrometers, a kind of a product that is hard to machine. Furthermore, using a micro-diameter endmill, it is easy to perform fine shape machining with many 30-micrometer ribs.

The fine shape remains undamaged, attributable to POTICON’s micro-level reinforcement.

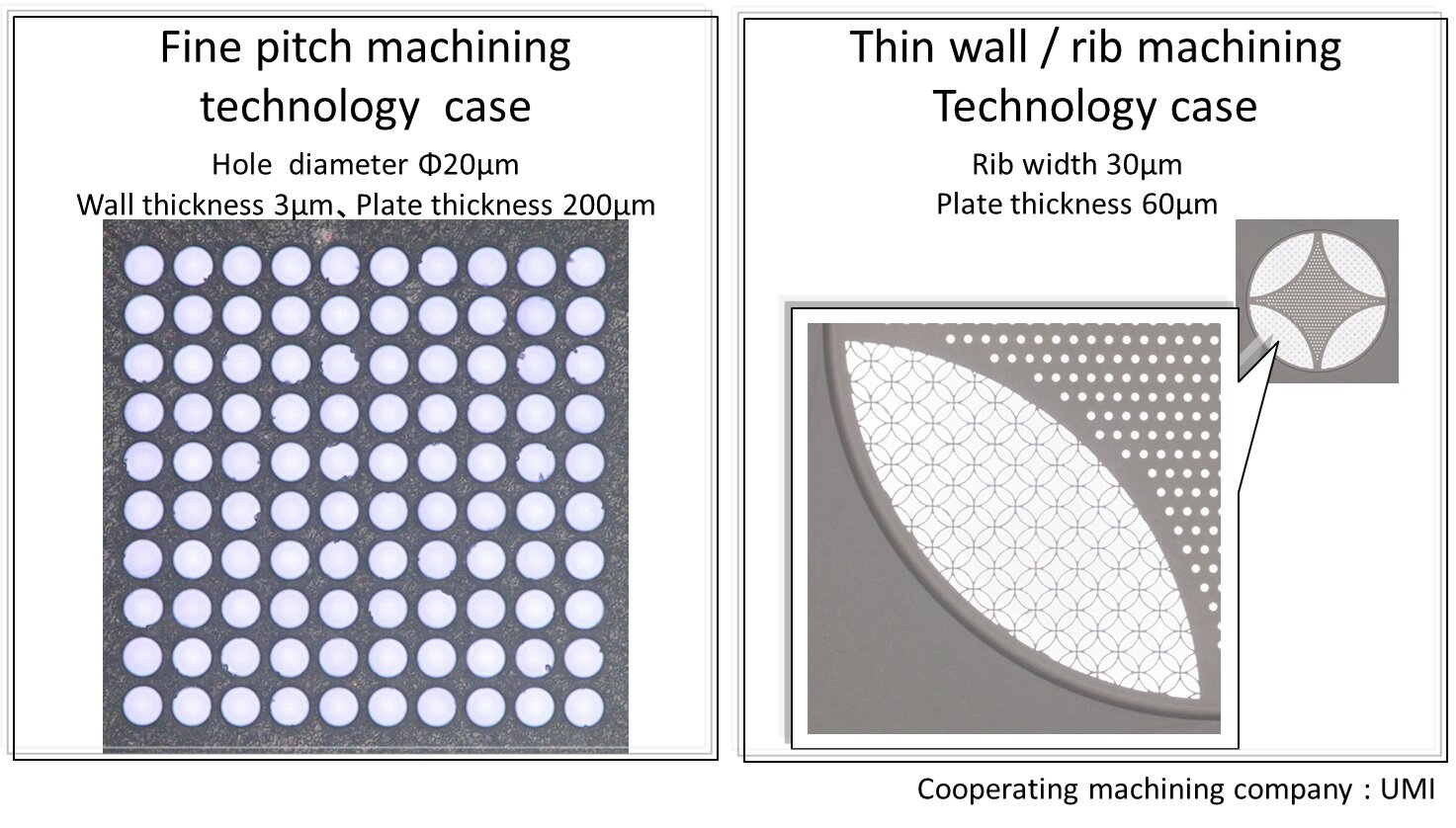

Good hole-position precision and limited burr formation

Hole diameter Φ30µm、Wall thickness 5µm、Plate thickness 200µm、No. of holes 5×5

When machined using a small-diameter drill, POTICON IT6Bplate materials have little hole eccentricity and high positional precision in comparison with other materials. There will be fewer burrs, which should increase the ease of high-precision cutting during micromachining.

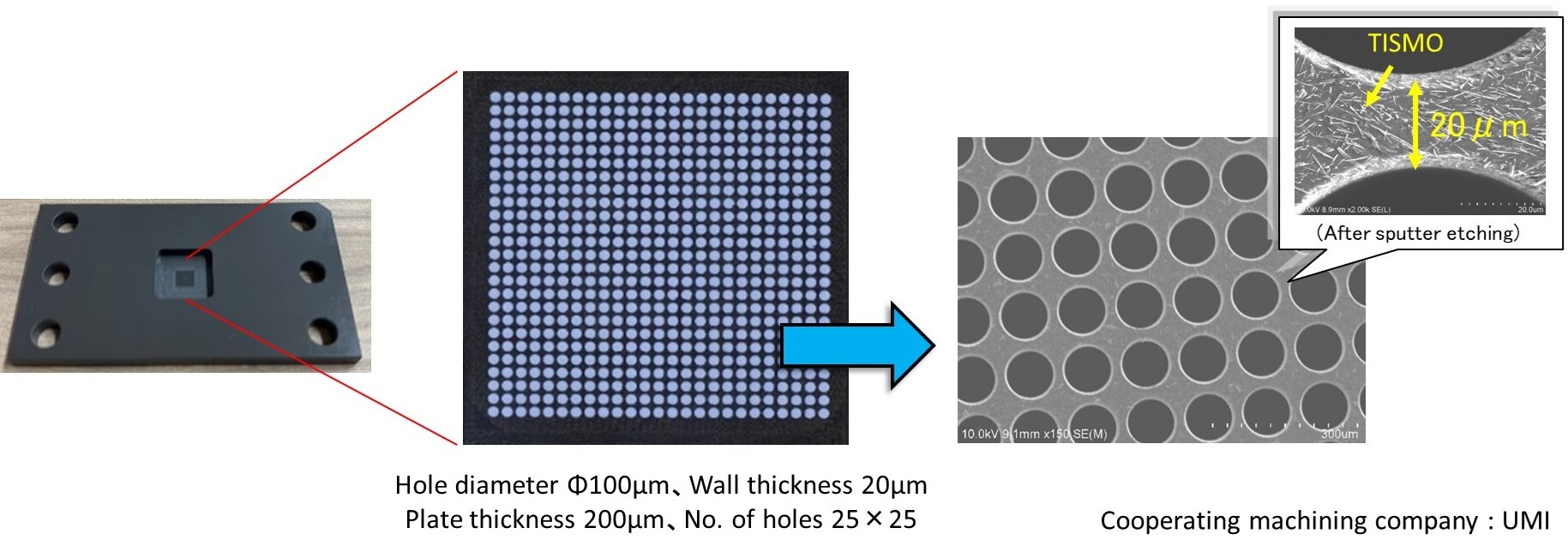

Micro-level reinforcement of micromachined products

Using a SEM to observe a micromachined product, it can be seen that TISMO uniformly disperses even in a very small area of 20 micrometers. The micro-level reinforcement makes it easy for a micromachined product to retain its shape and you can also expect the product to be more durable.

Development product

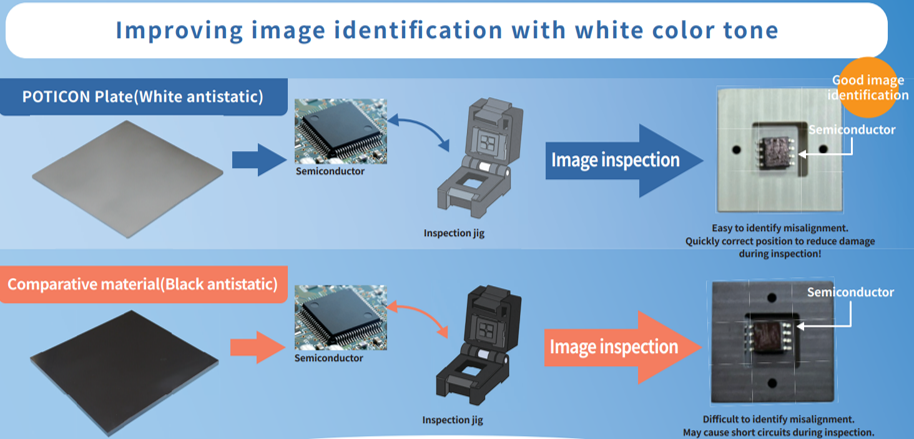

POTICON plate with white antistatic properties

PEEK-based POTICON plate with white antistatic filler “DENTALL” offers white coloration and stable antistatic performance that are not found in conventional materials.

In inspection processes for semiconductors with advancing high performance, it reduces static electricity damage and minimizes inspection errors by improving image identification.

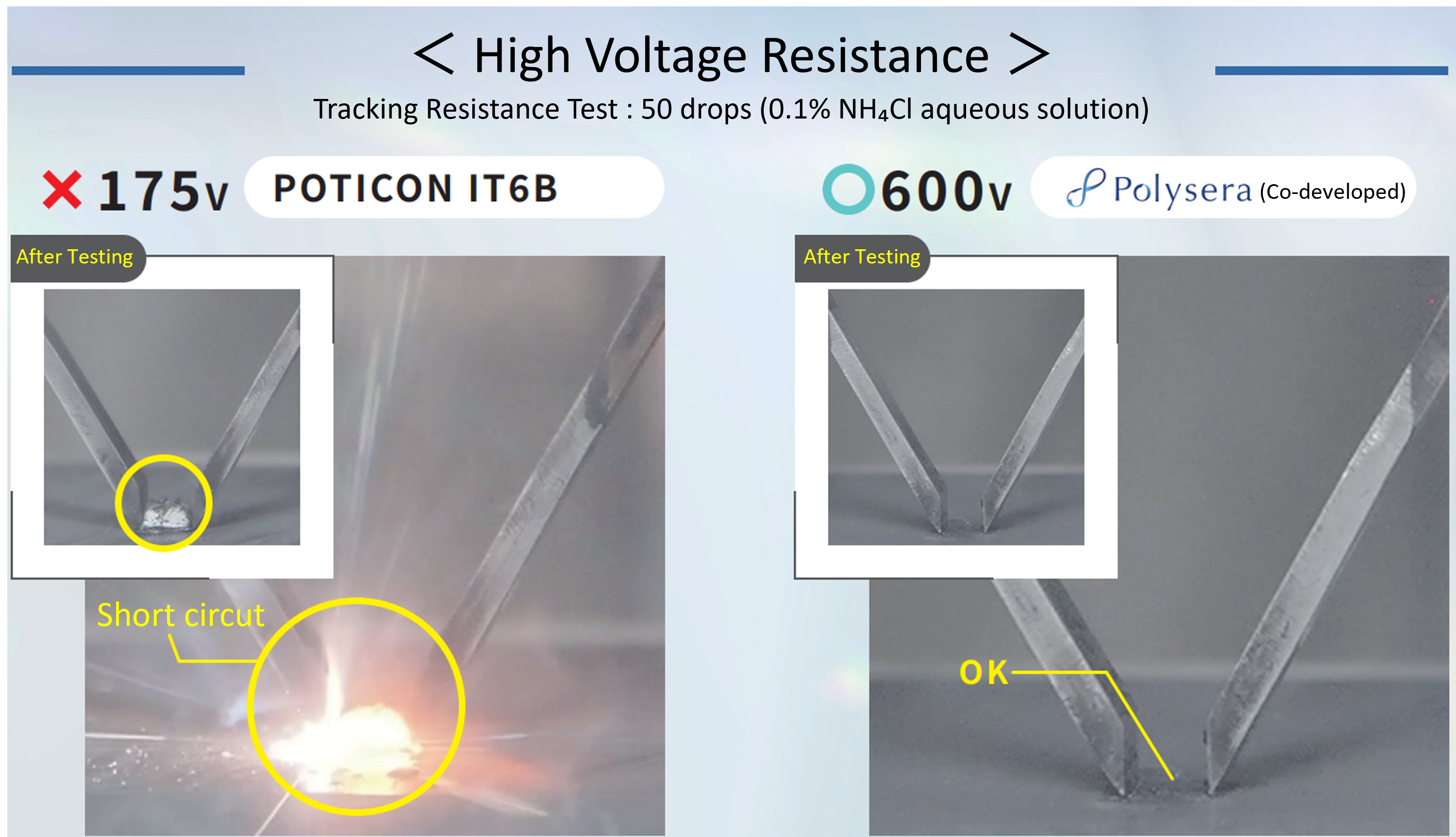

High-voltage-resistant “Polysera” (co-developed plate)

In addition to the good machinability that characterize POTICON plate, we have co-developed with Otsuka Chemical and UMI a plate with significantly improved tracking resistance. We will continue to develop high-voltage-resistant materials to meet the growing demand for higher voltage applications.

General Properties

| Grade | IT6B | IM6B | |

|---|---|---|---|

|

Features |

Ease of machining Smoothness |

Low dielectric Constant |

|

| Base Resin | PEI | PEI | |

| Specific gravity | g/cm3 | 1.57 | 1.54 |

|

Water absorption rate (after 24hr, 3mmt) |

% | 0.18 | 0.16 |

| Tensile strength | MPa | 110 | 126 |

| Flexural strength | MPa | 164 | 208 |

| Flexural modulus | GPa | 8.7 | 8.3 |

| HDT(1.82MPa) | ℃ | 211 | 202 |

| Thermal Expansion coefficient MD | ppm | 22 | 17 |

| Thermal Expansion coefficient TD | ppm | 29 | 38 |

| Dielectric Constant@1MHz | εr | 5.0 | 3.5 |

| Dissipation Factor@1MHz | tanδ | 0.06 | 0.003 |