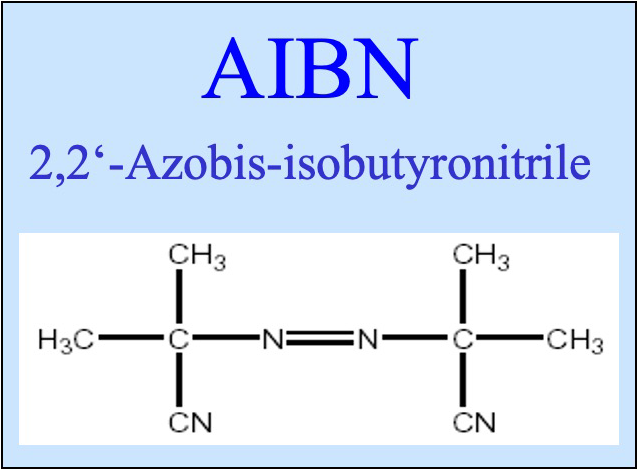

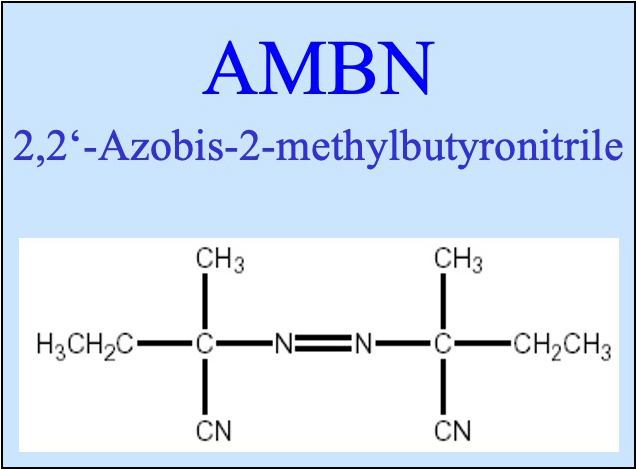

Otsuka Chemical is proud of its azoic polymerization initiators

Polymer chemistry technologies contribute greatly in many product categories including fibers, rubbers, resins, paints and adhesives. Catalytic chemistry is the foundation supporting these technologies. Otsuka Chemical sells a wide lineup of azoic polymerization initiator products that are able to meet diverse needs.

Solution

Azoic polymerization initiators begin polymerization when monomers react with radicals which are formed when dissolved in a solvent and heated. Compared to their peroxide counterparts, it is believed that these initiators result in more linear macromolecules. Furthermore, they are less impacted by the addition of solvents or metals which increases the ease of controlling and handling polymerization.

Physical properties

Applications of each polymerization initiator

| AIBN | AMBN | ADVN | ACVA | OTAZO-15 | |

|---|---|---|---|---|---|

| Methyl methacrylate | ⚫︎ | ⚫︎ | ⚫︎ | ⚫︎ | ⚫︎ |

| Vinyl chloride | ⚫︎ | ⚫︎ | ⚫︎ | ⚫︎ | |

| Vinyl acetate | ⚫︎ | ⚫︎ | ⚫︎ | ⚫︎ | ⚫︎ |

| ABS | ⚫︎ | ⚫︎ | ⚫︎ | ⚫︎ | |

| Styrene | ⚫︎ | ⚫︎ | ⚫︎ | ⚫︎ | ⚫︎ |

| Acrylic acid ester | ⚫︎ | ⚫︎ | ⚫︎ | ⚫︎ | ⚫︎ |

| Acrylonitrile | ⚫︎ | ⚫︎ | ⚫︎ | ⚫︎ | |

| SBR | ⚫︎ | ⚫︎ | ⚫︎ | ⚫︎ | |

| Acrylamide | ⚫︎ | ||||

| Polyol | ⚫︎ | ⚫︎ | ⚫︎ | ⚫︎ | |

| Butadiene | ⚫︎ | ⚫︎ | ⚫︎ | ⚫︎ | ⚫︎ |

| Acrylic acid | ⚫︎ | ⚫︎ | ⚫︎ | ⚫︎ | ⚫︎ |

| Methacrylic acid | ⚫︎ | ⚫︎ | ⚫︎ | ⚫︎ | ⚫︎ |

Solubility of each polymerization initiator

| AIBN | AMBN | ADVN | ACVA | OTAZO-15 | |

|---|---|---|---|---|---|

| Water | <0.1 | <0.1 | <0.1 | <0.1 | <0.1 |

| Methanol | 6.1 | 113 | 63 | 8.5 | 1.6 |

| Acetone | 28 | 263 | 213 | 1.5 | 13 |

| Benzene | 10 | 183 | 176 | <0.1 | 19 |

| Toluene | 4.6 | 153 | 129 | <0.1 | 8.4 |

| Xylene | 2.1 | 103 | 91.1 | <0.1 | 4.2 |

| n-Hexane | 0.1 | 2.4 | 10 | <0.1 | 0.3 |

| DMF | 7.2 | 87.3 | 35 | 48.2 | 2.7 |

| DMSO | 19.8 | 192 | 121 | 84.5 | 13.4 |

| Styrene | 5.7 | 146 | 118 | <0.1 | 9.6 |

| MMA | 7.3 | 137 | 104 | <0.1 | 9.3 |

※ACVA dissolves in water when turned into sodium salt

Chemical properties

| AIBN | AMBN | ADVN | ACVA | OTAZO-15 | |||

|---|---|---|---|---|---|---|---|

| Molecular weight | 164.2 | 192.3 | 248.4 | 280.3 | 354.4 | ||

| Melting point(℃) | 100~103 | 48~52 | 45~70 | 110~120 | 106~110 | ||

| Decomposition point(℃) | 100~103 | 105~107 | 97~99 | 110~120 | 106~110 | ||

| 10hours. half-life(℃) | 65 | 67 | 52 | 68 | 61 | ||

| Existing chemicals substances No. | 2-1531 | 2-3539 | 2-161 | 2-2794 | 3-4301 | ||

| CAS RN® | 78-67-1 | 13472-08-7 | 4419-11-8 | 2638-94-0 | 57908-47-1 | ||

| EINECS No. | 2011323 | 2367408 | 2245838 | 2201350 | - | ||

| Fire Service Act No. | 5-II | 5-II | 5-II | Nonhazardous material | Nonhazardous material | ||

|

Poisonous and Deleterious Substances Control Law |

Deleterious Substances |

Deleterious Substances |

Deleterious Substances |

n/a | n/a |

Applications

Manufacturing of plastic products

Manufacturing of paints and coatings

Azoic polymerization initiators also play important roles in the manufacturing of paints and coatings. These products are extensively used in many different industries, including the construction, automobiles and aerospace industries.

Fibers and fiber processing

Azoic polymerization initiators are also used to manufacture fibers and fiber products. For example, they are used to initiate polymerization in the process of manufacturing synthetic fibers and fiber products.