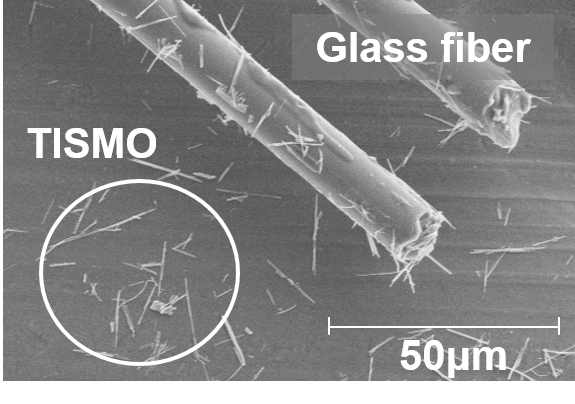

DENTALL is a conductive product with the same characteristics of TISMO

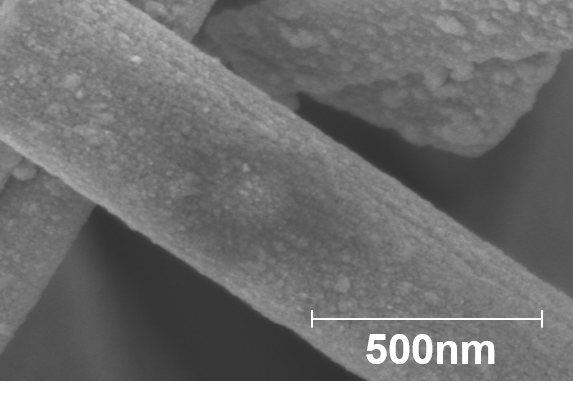

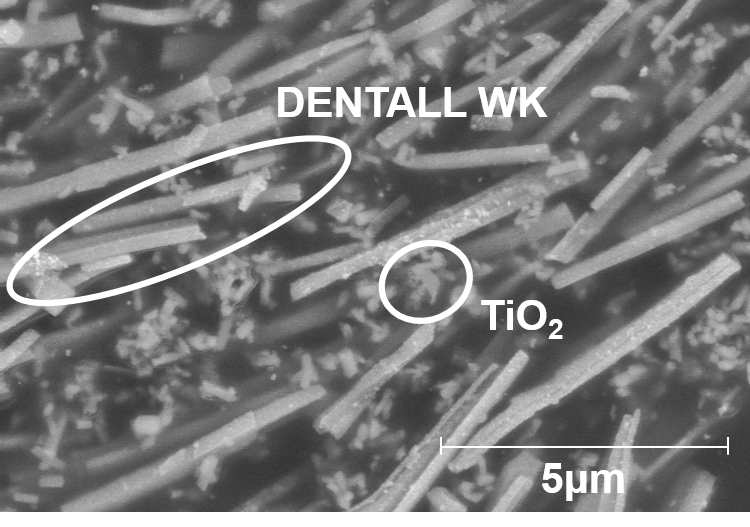

DENTALL is a white, conductive filler made by uniformly coating the surface of a white potassium titanate fiber (TISMO) derivative with a nano-ordered transparent conductive layer. Adding DENTALL to a material such as a paint, an adhesive, film or resin molding can enable conductivity without compromising the material's whiteness.

Advantages

Uniform and consistent conductivity

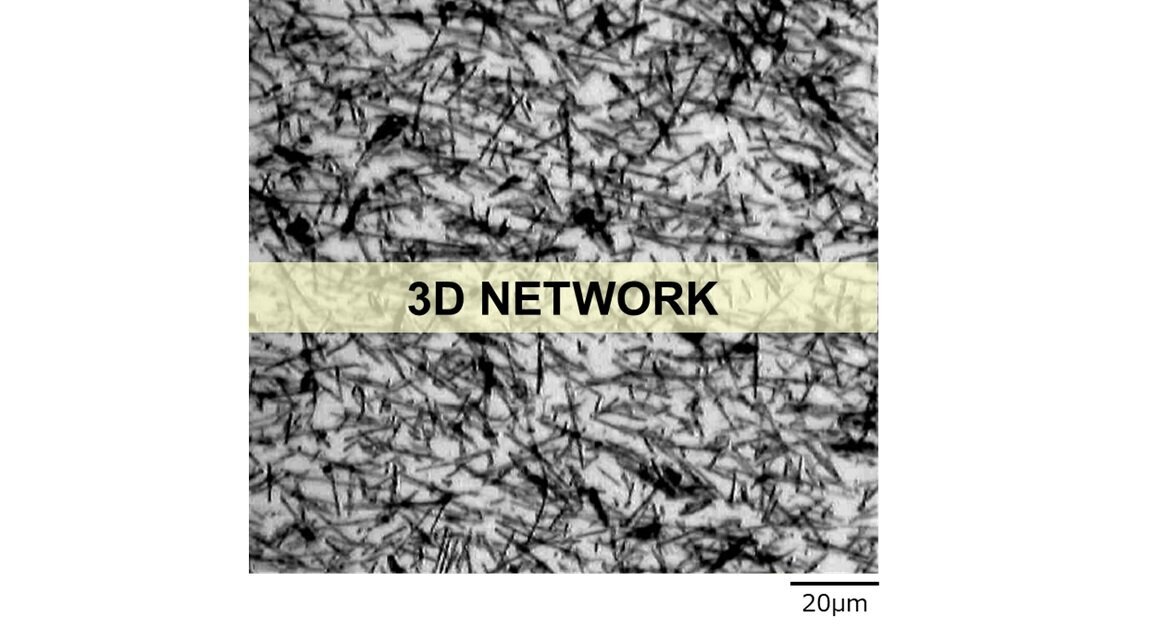

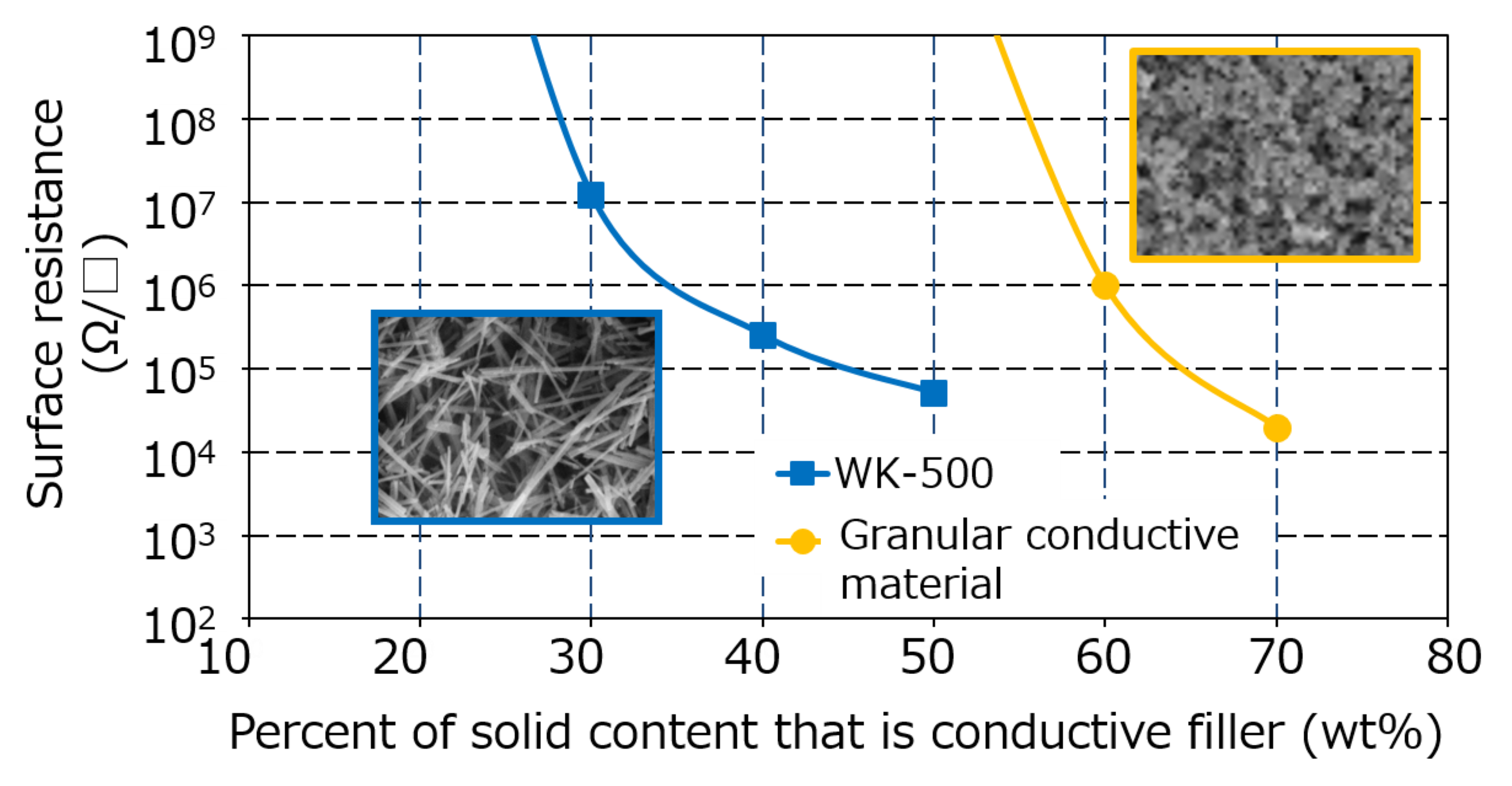

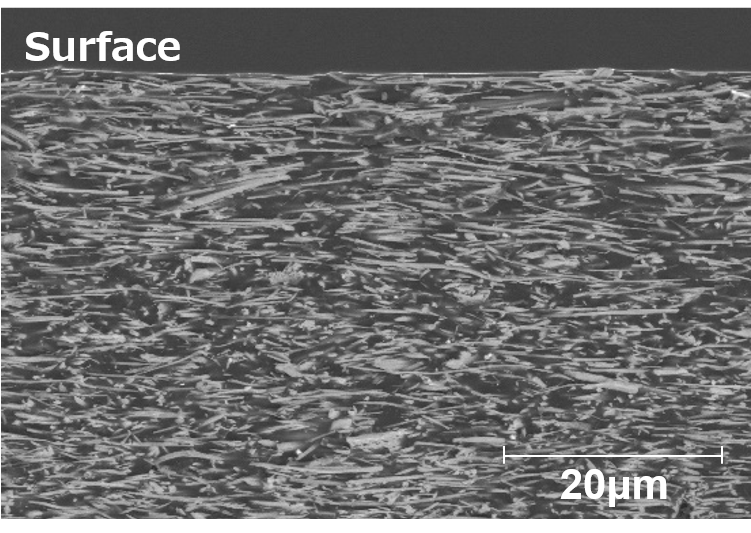

The fiber-shaped conductive path of DENTALL is formed by the linear contact of these fibers (microscopically on the surface). By forming a conductive path with a three-dimensional network structure, it is possible to achieve consistent conductivity and minimize variations in the surface resistance of coating films. Because conductive paths are easily formed, it is possible to achieve conductivity at an antistatic level using less product than when using a granular conductive material, and stable performance can be achieved with fewer fluctuations due to the amount of additive used.

Enabling conductivity in a micro-scale area

When blending a conductive filler such as carbon fiber into a resin, ensuring the conductivity of micro-scale resin areas where no conductive pathway has been formed becomes an issue, but using DENTALL microfibers can ensure that uniform conductive pathways are formed throughout the resin.

Thin-film conductivity and surface smoothness

With its TISMO-derived fine shape and uniformity, DENTALL can form good conductive pathways even with films as thin as approxamately 10 micrometers. It can also enable surface smoothness.

General Properties

| Grade | Unit | WK-500 | WK-500B | WK-500C |

|---|---|---|---|---|

| Chemical composition | - | TiO2 / SnO2 (Sb) | TiO2 / SnO2 (Sb) | TiO2 / SnO2 (Sb) |

| Appearance | - | Light gray powder | Light gray powder | Light gray powder |

| Electrical resistance1) | Ω | 100~1 | 100~1 | 10-1~0 |

| Whiteness | L value | >76 | >76 | >68 |

| Average fiber length | μm | 5〜15 | 5〜15 | 5~15 |

| True density | g/cm3 | 3.5〜4.0 | 3.5〜4.0 | 3.5~4.0 |

| Bulk density | g/cm3 | 0.2〜0.4 | 0.2〜0.4 | 0.2~0.4 |

| Water content | % | <2 | <2 | <2 |

| pH (dispersed in water) |

- | 2〜4 | 6〜9 | 3~6 |

| Specific surface area2) | m2/g | 15〜25 | 10〜25 | 10~25 |

1)Otsuka method, 2) BET method

Applications

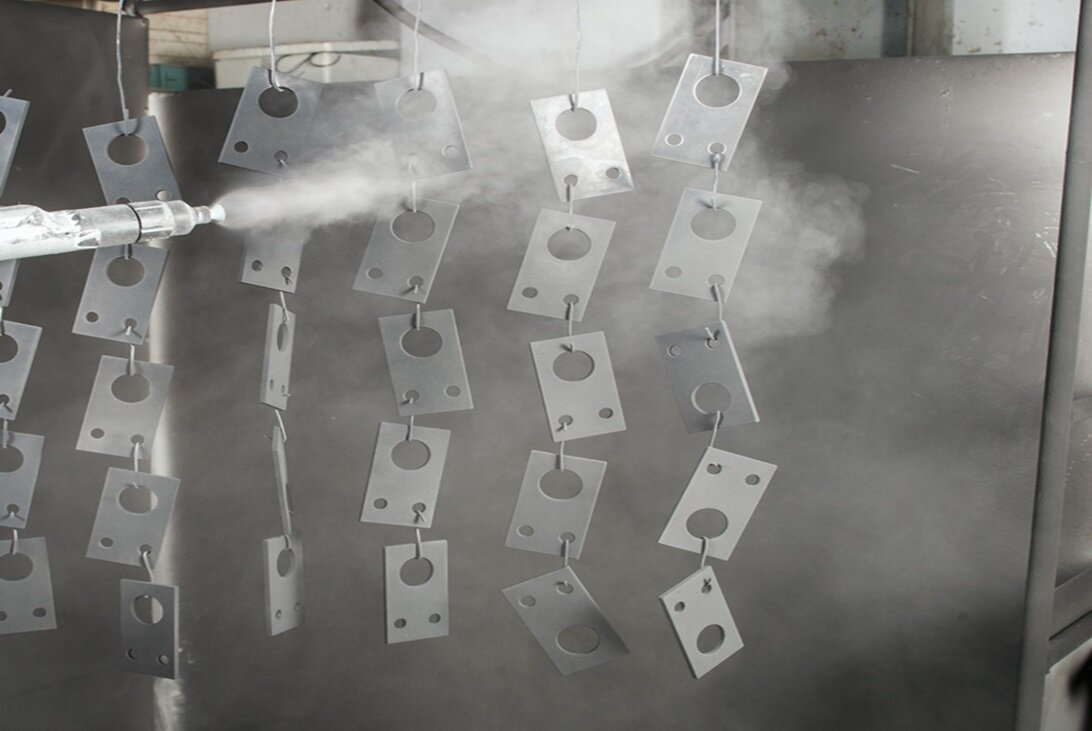

Primers for electrostatic coating of parts of automobiles and two-wheeled vehicles

Antistatic paints for floors and walls

Precoated metal

Conductive films

Office automation equipment parts

Powder paints