Additives shall expand the possibilities of rubber.

Otsuka Chemical develops and distributes special organic chemicals to be added to different types of rubber, leveraging its organic synthesis technologies, including hydrazine derivatives. Its mainstay products are special organic chemicals that can improve the fuel economy performance and durability of automobile tires. Tires are important components that relate to the safety, environmental performance and comfort of cars. The performance of tires is affected greatly by the properties of the rubber materials used. World-first original compounds developed by Otsuka Chemical have been adopted for use in rubber materials for high-performance tires. Although these compounds are not conspicuous because they are found in only small amounts in rubber materials, they contribute greatly to today's mobility society. In particular, chemical technologies for fuel-efficient tires—which lead to improved fuel economy in cars—contribute to a reduction in carbon dioxide on earth, also leading to reductions in environmental impact.

| Grade | DS-01T | EN-01 |

|---|---|---|

| Compatible polymers | SBR/BR | Natural rubber |

| Conforming Filler | Silica | Carbon black |

| Effect | Silica dispersion | Carbon Dispersion |

| Improved physical properties | Low power consumption | Tear strength |

| Application examples | Passenger Car Tires Cap tread rubber |

Large Tires Tread and case rubber |

Solution

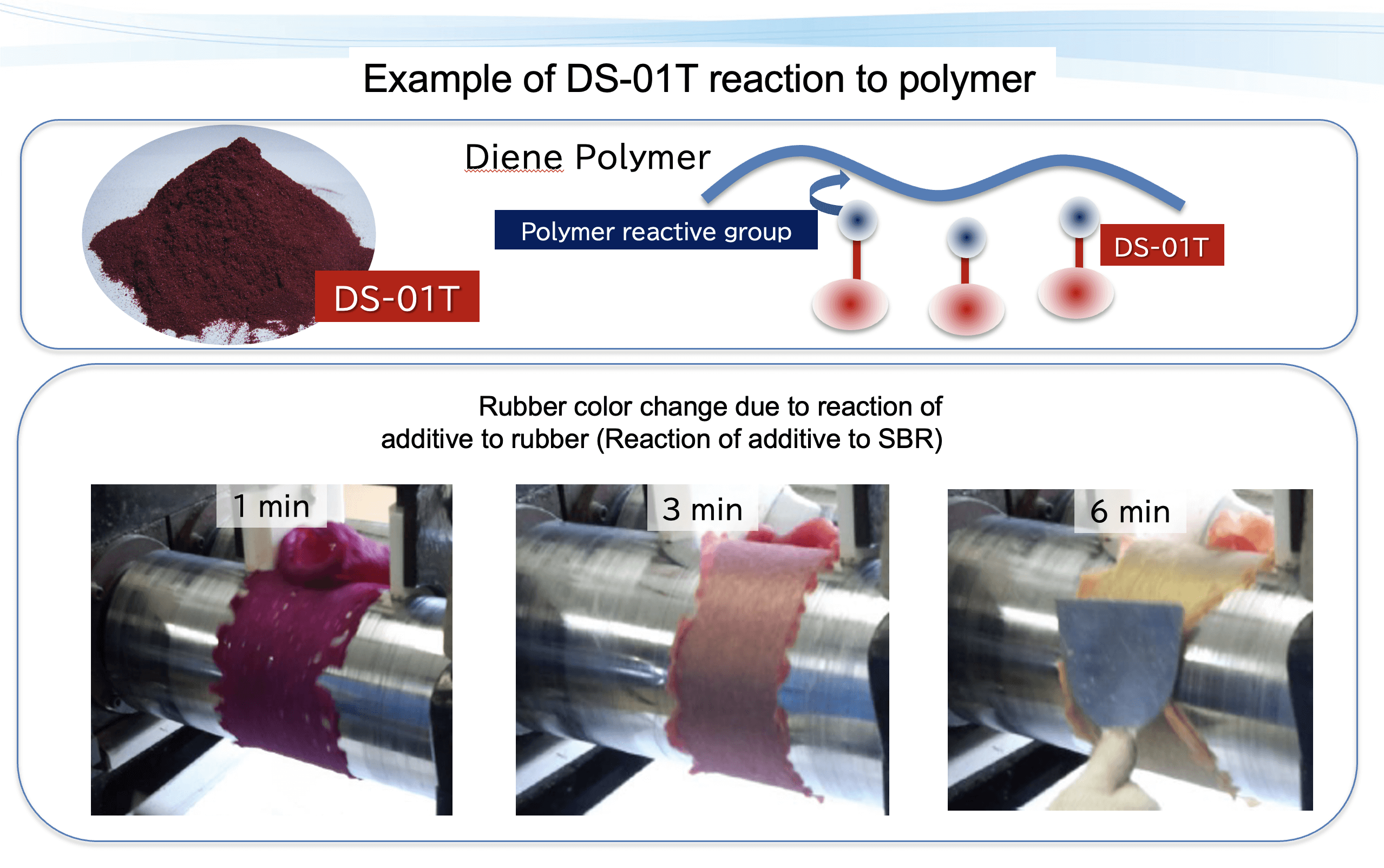

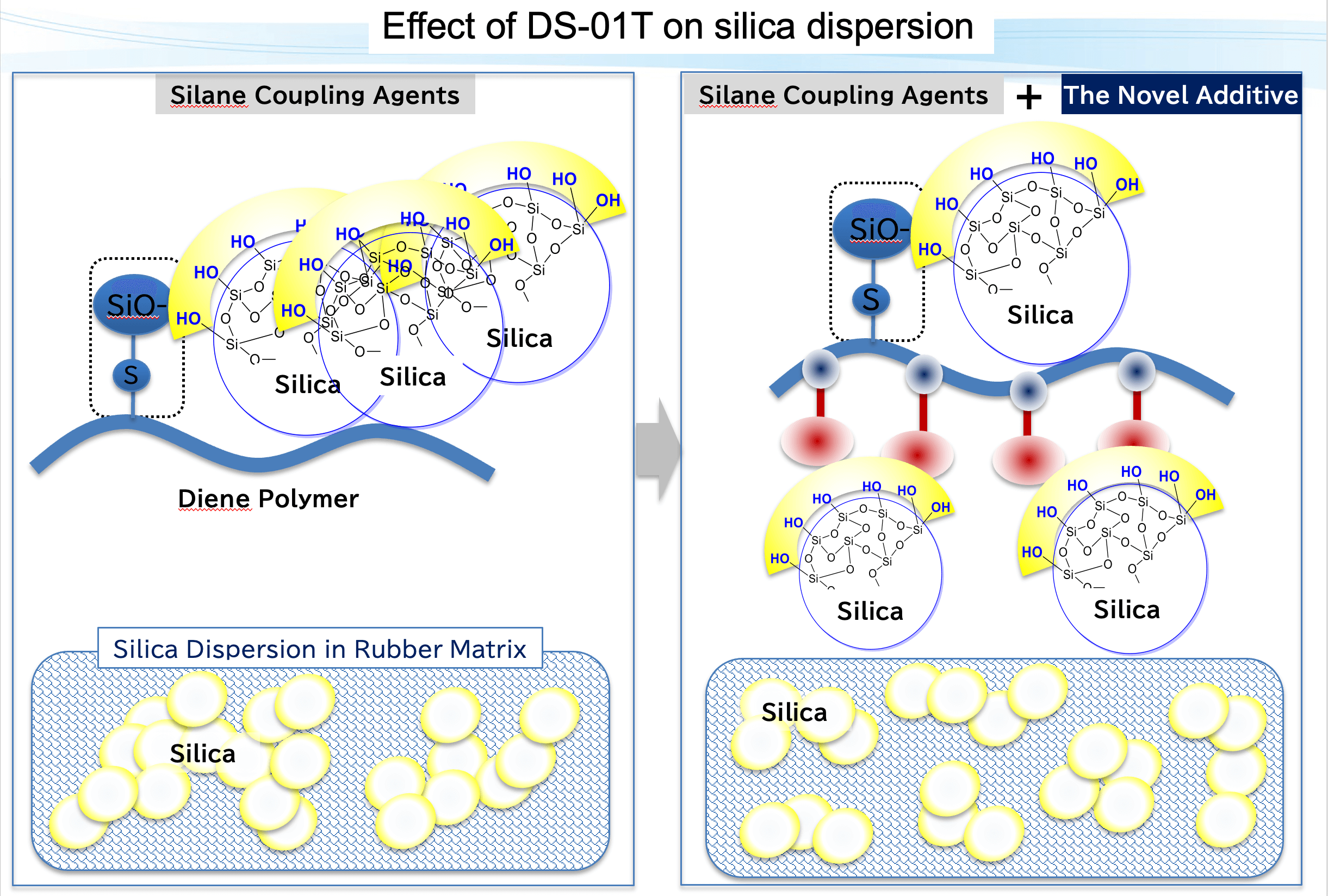

When Acroad is added to natural or synthetic rubber, it improves the dispersibility of fillers.

Through the reaction of a very small quantity of additive with polymer molecules of rubber during the mixing process, the rubber gains affinity for carbon black or silica that serve as fillers. This affinity of the rubber molecules significantly improves the dispersibility of carbon black, silica and other fillers in the rubber when they are added during the mixing process. When an additive increases the dispersibility of the fillers in the rubber, it significantly increases the various physical properties of vulcanized rubber. We offer optimal additives according to the type of rubber and fillers.

Advantages

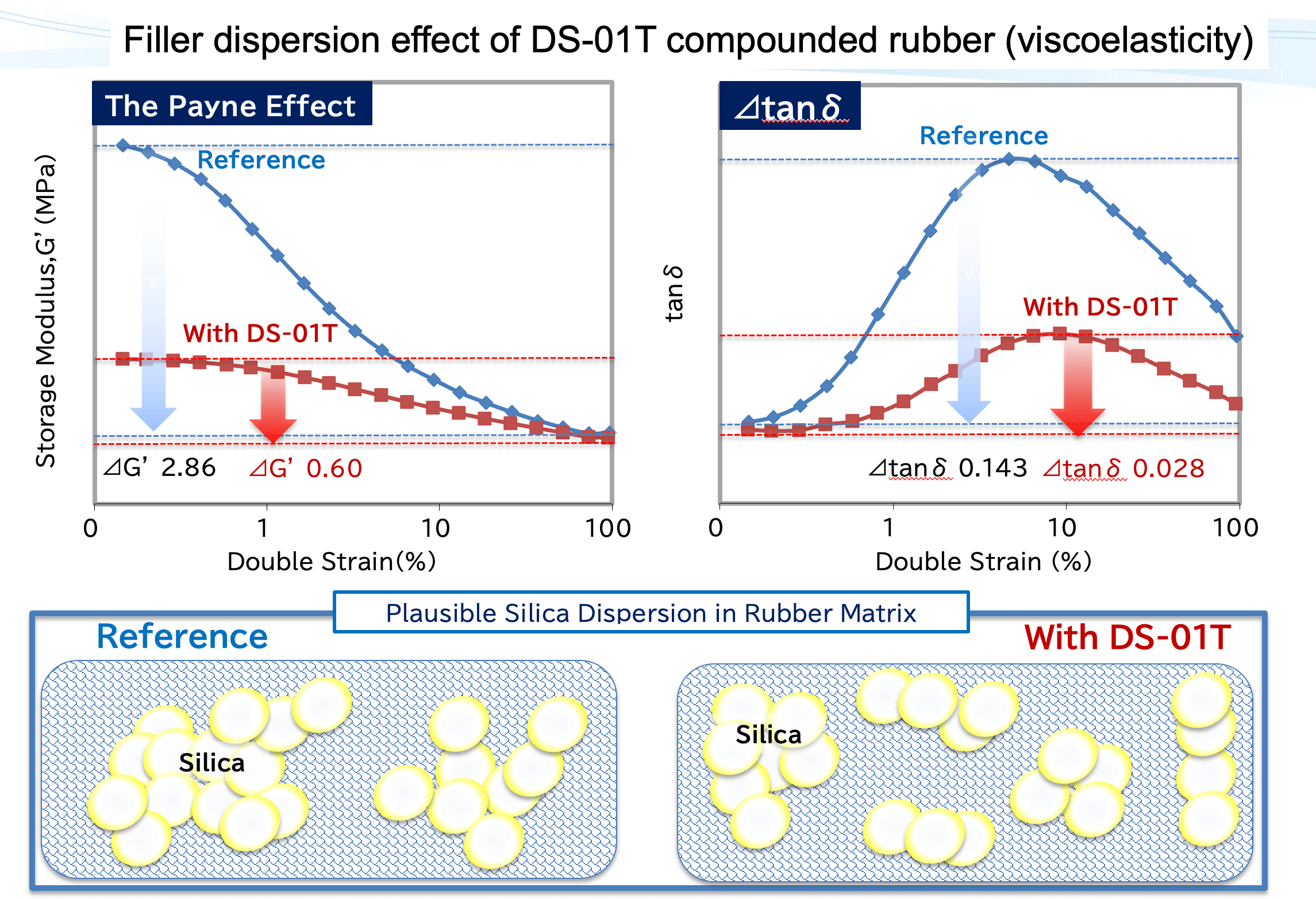

Low heat build-up properties

The vulcanized rubber, which is made by adding a small amount (0.2 to 2.0 phr) of DS-01T (silica-containing synthetic rubber) or DC-01T (carbon black-containing natural rubber) during the rubber mixing, improves the dispersibility of fillers, having the very low heat emission property. Such additives will work effectively if an appropriate additive is selected and mixed according to type of rubber/filler.

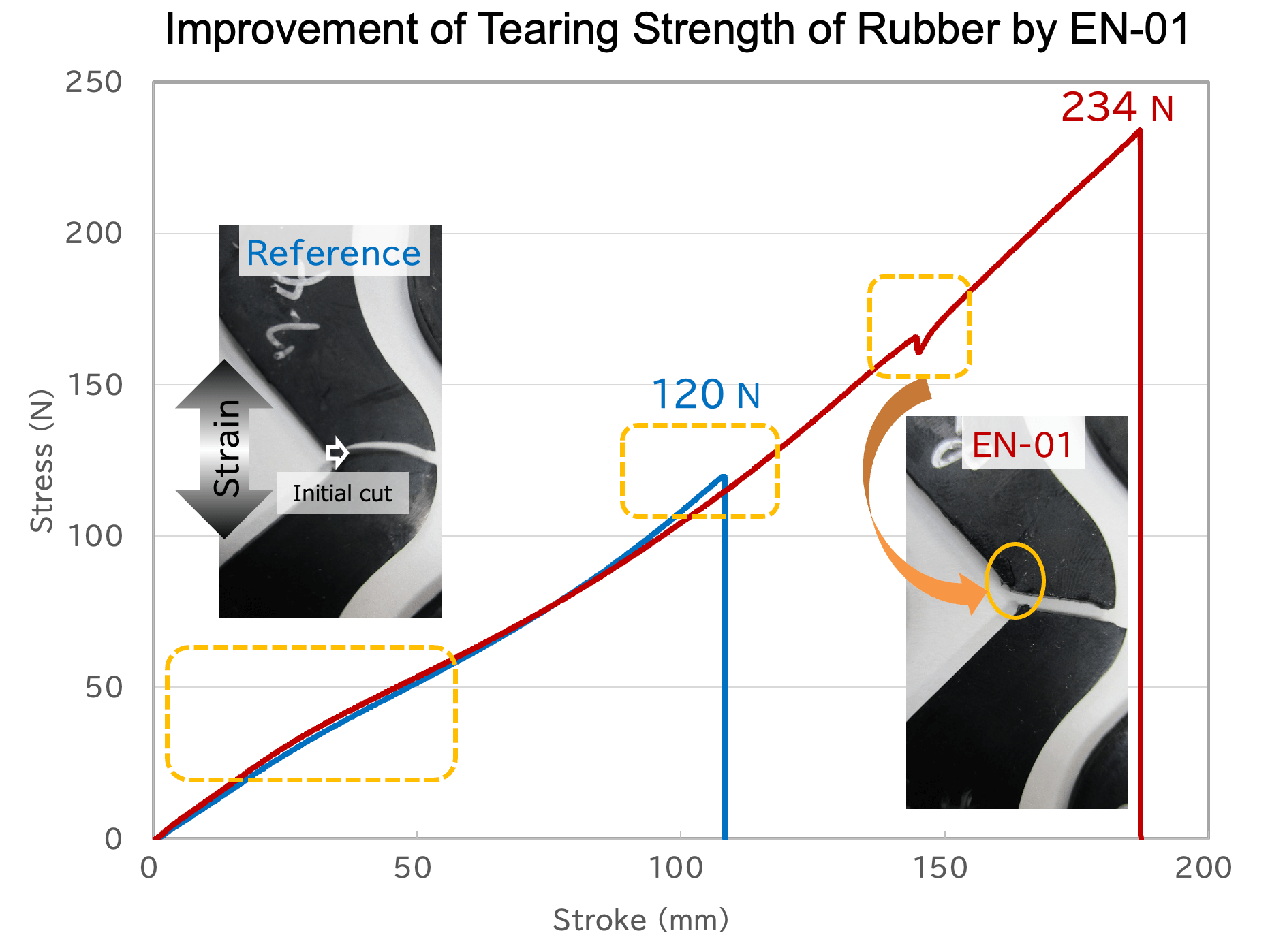

Durability

If a small amount (0.6 to 1.2 phr) of EN-01 is added to rubber during mixing, the resulting vulcanized rubber will have the equal heat emission property and the remarkably elevated tearing performance. As a result, the tear resistance of rubber products will increase, and the life of rubber products will be prolonged since the processing suppresses crack advance.

Physical properties

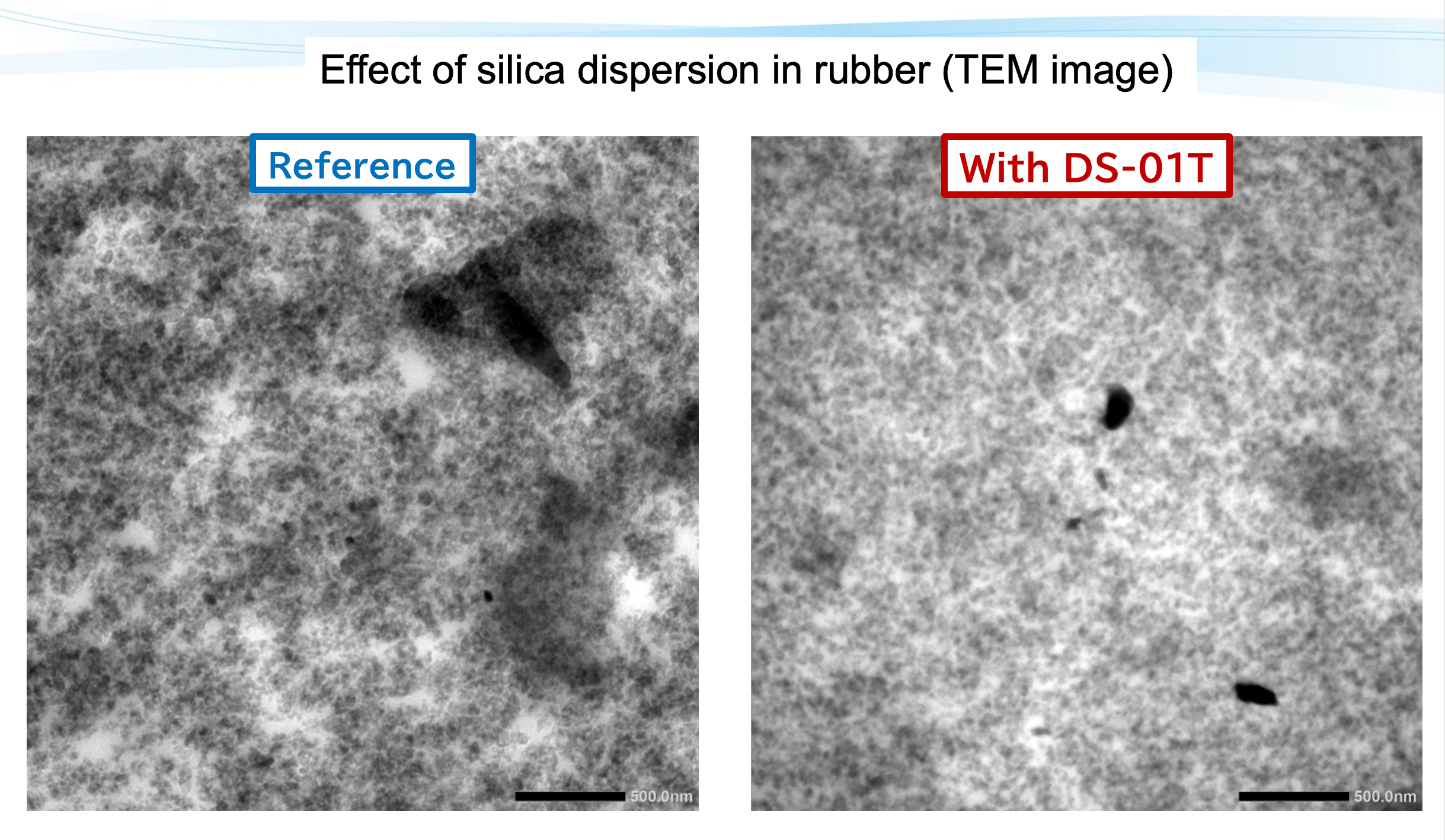

Example of combination of vulcanized rubber when DS-01T (silica-containing synthetic rubber) is added.

| Example of combination | Reference | DS-01T |

|---|---|---|

| S-SBR | 80 | 80 |

| butadiene rubber | 20 | 20 |

| DS-01T (oil15wt%) | - | 1.17 |

| silica | 80 | 80 |

| silane coupling agent | 6.4 | 6.4 |

| carbon black | 5.0 | 5.0 |

| Other | 7.5 | 7.5 |

| Oil (total) | 45 | 45 |

| CBS | 2.0 | 2.0 |

| DPG | 1.2 | 0.6 |

| sulfur | 1.0 | 1.0 |

Example of physical property of vulcanized rubber when DS-01T (silica-containing synthetic rubber) is added.

| physical properties | Reference | DS-01T |

|---|---|---|

| Mooney viscosity(ML1+4/100 ℃) | 92 | 110(Index 120) |

| scorch(130℃/min) | 24 | 17(Index 70) |

| hardness(Shore A) | 62 | 61 |

| Tensile strength(23℃/MPa) | 19.9 | 20.3 |

| tensile strain(%) | 560 | 520 |

| viscoelasticity | ||

| G'min(MPa) | 1.04 | 1.00 |

| G'max(MPa) | 3.90 | 1.60 |

| G'max(MPa)-G'mio (MPa) | 2.86 | 0.60 |

| tanδ(max) | 0.303 | 0.184(Index 61) |

| tanδ(max)-tanδ(0. 1%) | 0.143 | 0.028(Index 20) |

Applications

- Rubber for large tires (carbon black-containing natural rubber)

- Rubber for small tires (silica-containing synthetic rubber)

- Anti-vibration rubber/rubber for belt conveyors

- Other industrial rubber products

- Natural rubber raw materials

Achievements

Tire rubber for trucks and buses/tire rubber for passenger cars/anti-vibration rubber/other products

Our additives are used in rubber for large tires, tire rubber for passenger cars, and other products in many different countries, contributing to increased fuel economy performance and durability. The additives are blended into anti-vibration rubber for automobiles as well, contributing to the increased performance of anti-vibration rubber.