KATACHI Business Gears/Precision Molded Parts

Providing molded gears and precise components

Leveraging the technology cultivated in the use of POTICON, we provided these molded products.We provide comprehensive solutions related to gears.

●We use simulation analysis to present potential metal alternatives

●We also undertake prototyping and mass production using non-POTICON materials.

POTICON Gear

Optimal for small modules and small-sized gears

POTICON gears have the micro-reinforcement, surface smoothness and excellent sliding properties characteristic of POTICON, making it possible to replace metal gears with resin and to use torques that are higher than conventionally used.

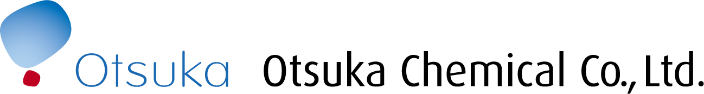

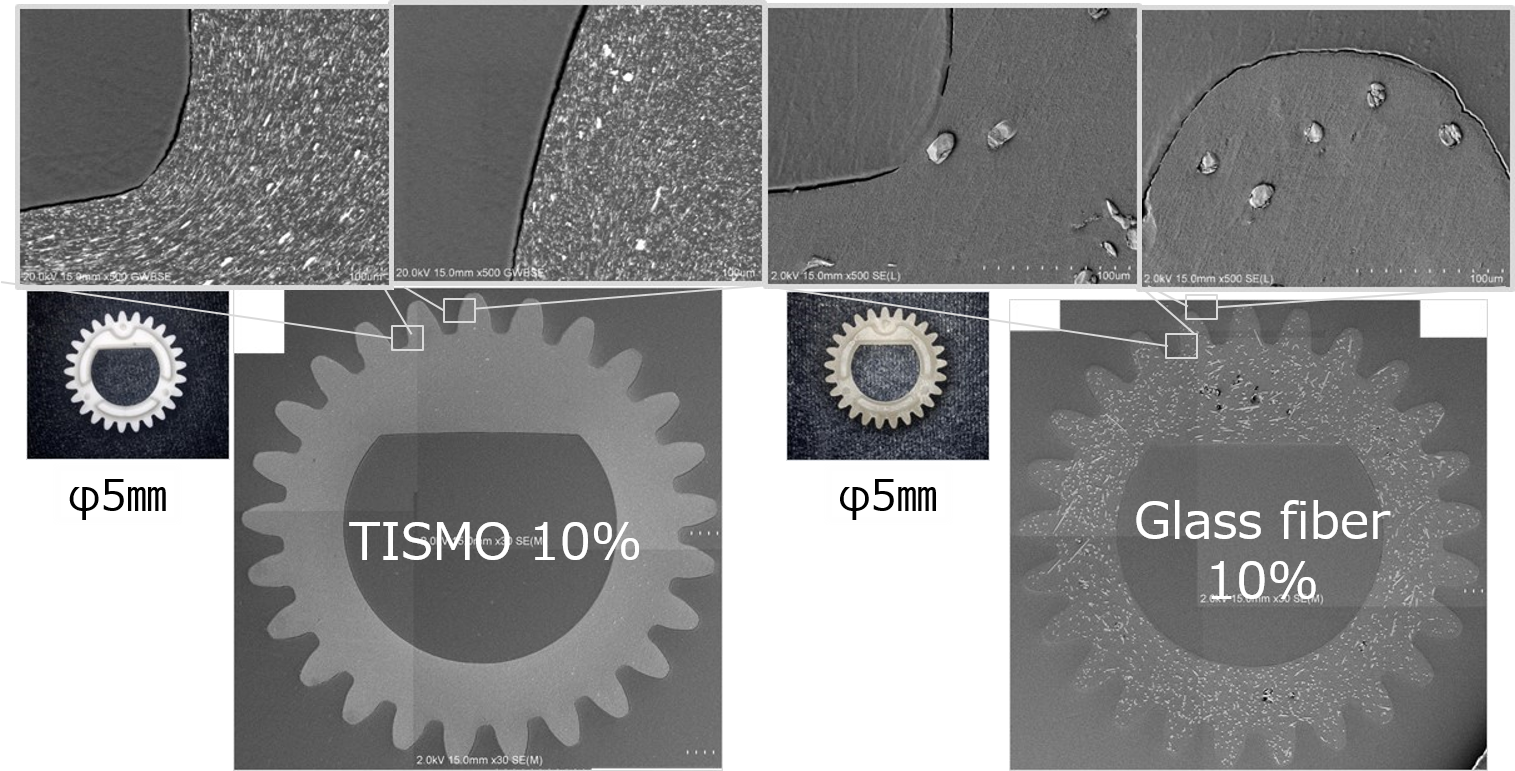

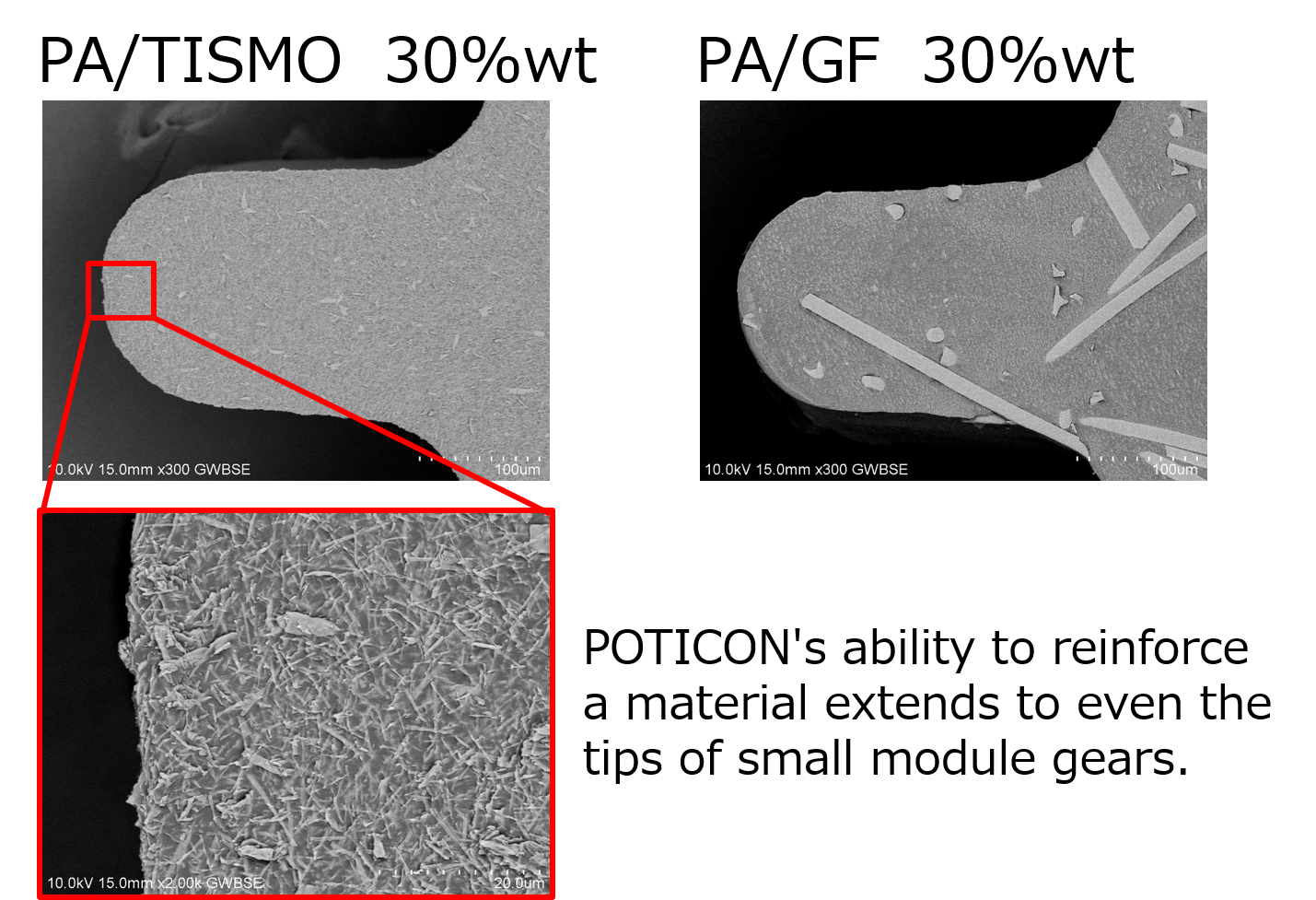

Micro reinforcement

Reinforced up to the tip of a small gear

TISMO, our unique microfiber, reinforces a complex small component to its tip.It has excellent strength, thermal deformation temperature and thermal expansion characteristics and also has dimensional stability advantages when sliding.

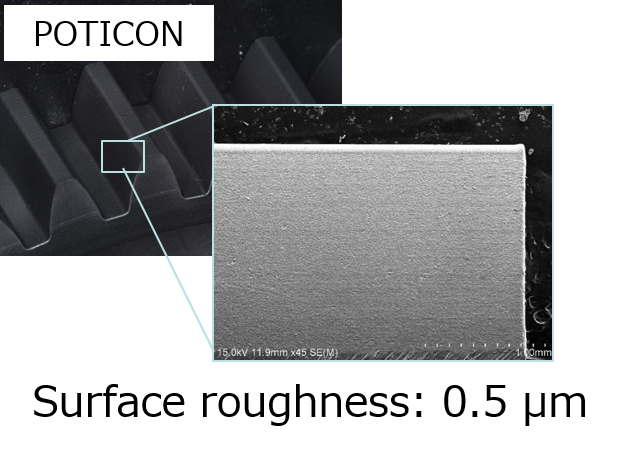

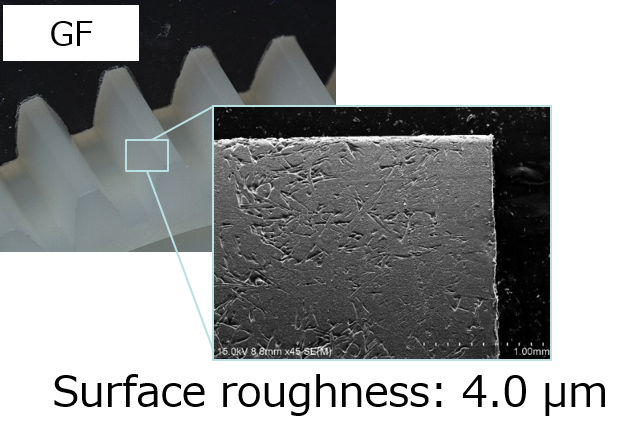

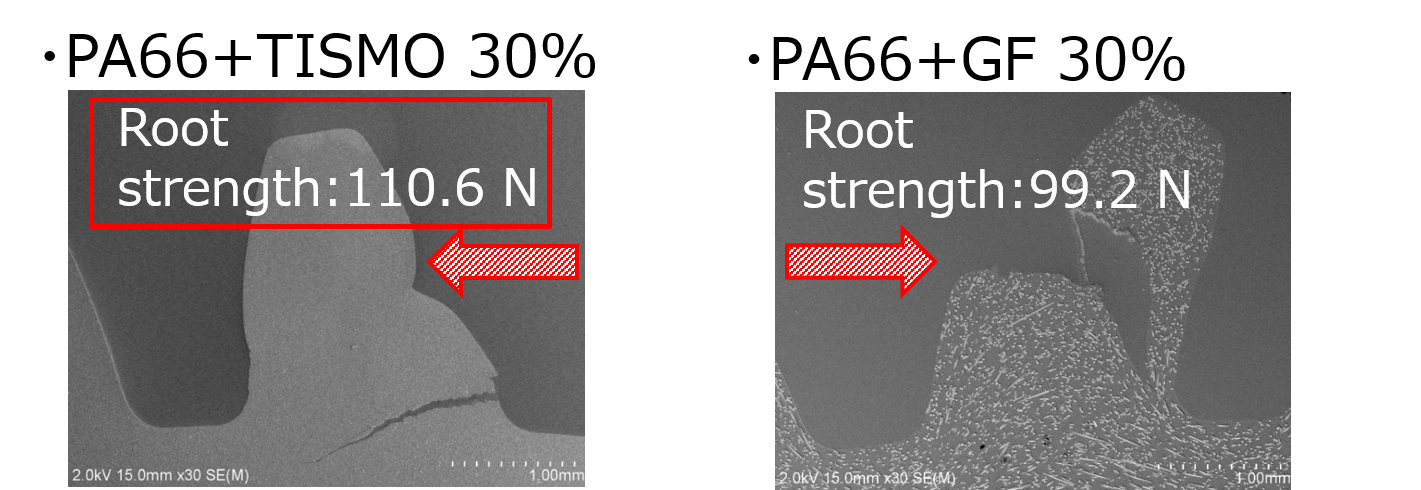

TISMO's dispersibility and orientation are good at the tip and root. The dispersion of glass fiber is poor.

GF reinforced products with simple shapes can have high strength, but POTICON is more effective for complicated shapes because it is a TISMO reinforced product.

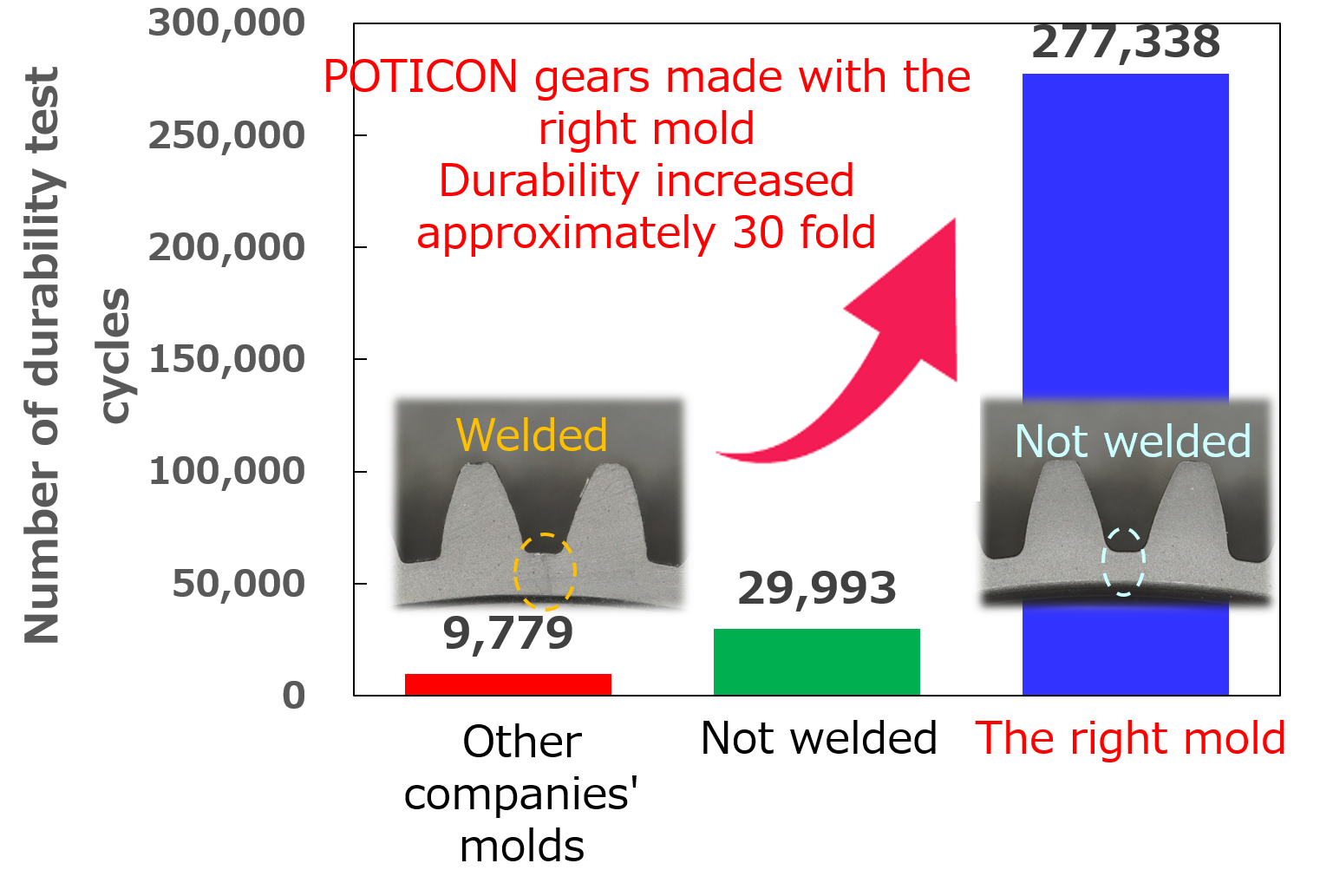

Providing products made using the right mold

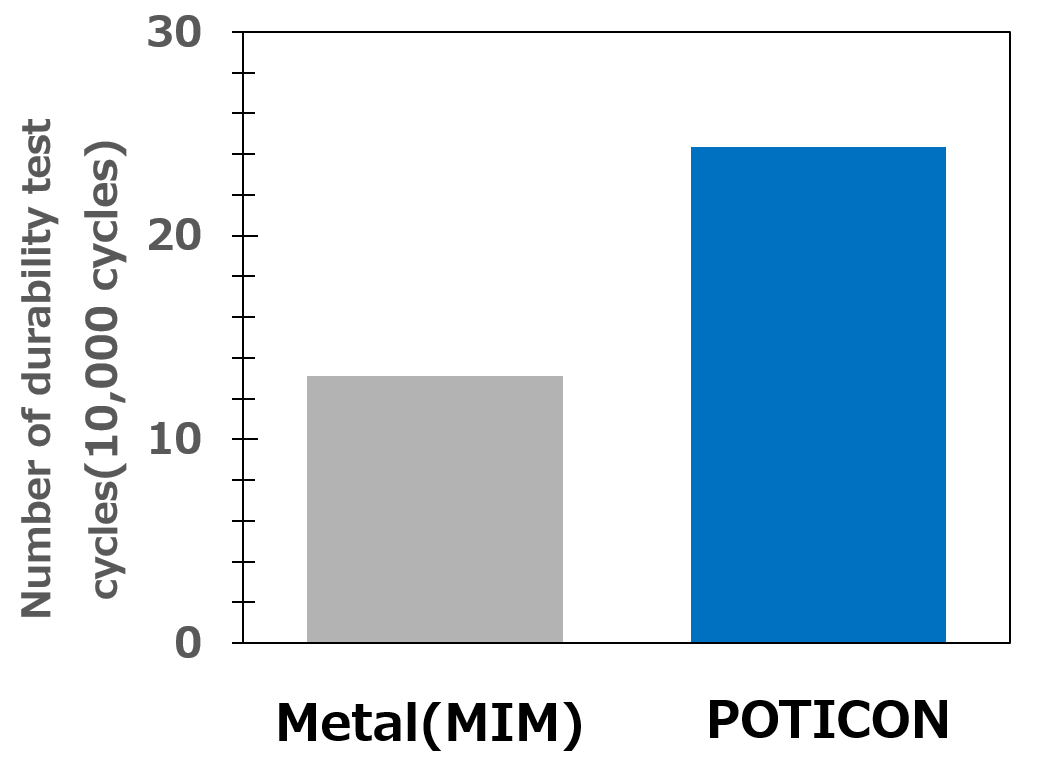

As POTICON contains microfibers, using the right mold can draw out the potential of POTICON gears in terms of their durability.

POTICON gears are used as alternatives to small-sized metal gears.

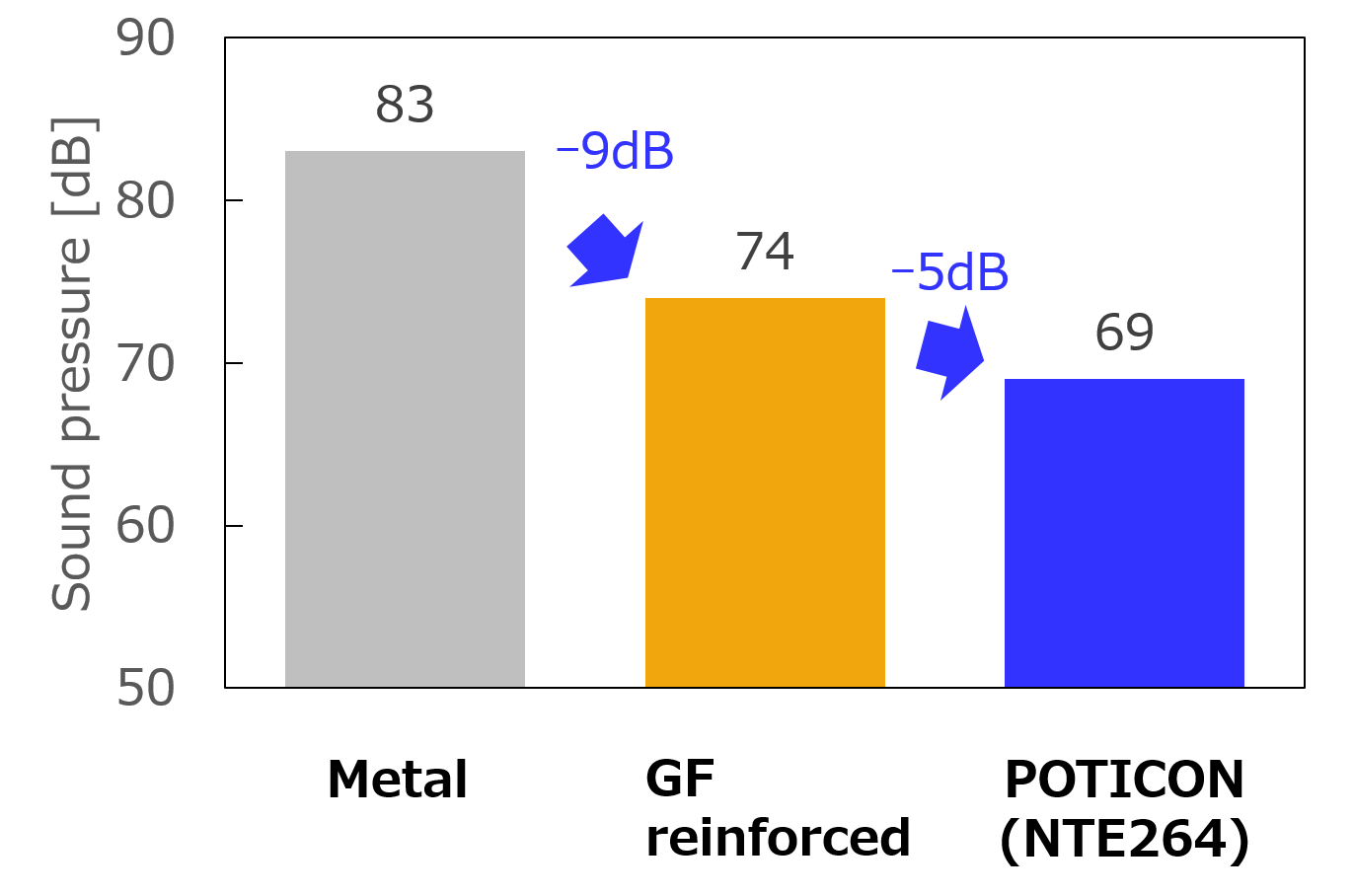

Quietness

Good surface smoothness and sliding properties enable the product to excel in gear quietness. It is used in applications that require quietness.

General Properties

| Polymer/Grade | POM | PA | ||||||

|---|---|---|---|---|---|---|---|---|

| AT342 | OA30 | NT363 | NCF263 | NTU46Z | NCT651S | |||

| Tensile strength | MPa | 82 | 111 | 150 | 231 | 133 | 196 | |

| Flexural strength | MPa | 121 | 169 | 238 | 307 | 179 | 290 | |

| Flexural Modulus | GPa | 6 | 9 | 11 | 15 | 9 | 13 | |

| IZOD impact strength | J/m | 39 | 44 | 31 | 121 | 241 | 53 | |

| Mold shrinkage rate | MD | % | 1.2 | 0.7 | 0.5 | 0.1 | 0.2 | 0.3 |

| TD | % | 1.9 | 1.4 | 1.0 | 1.3 | 1.0 | 0.7 | |

| HDT Heat distortion temperature (1.8MPa) | °C | 147 | 153 | 200 | 250 | 162 | 287 | |

Other resins are also available, please contact us.