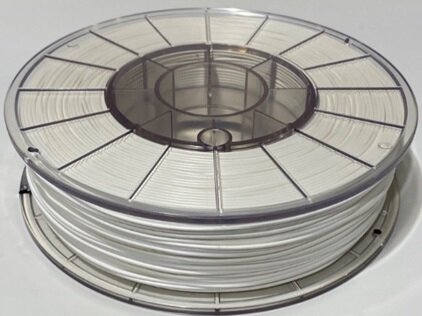

Resin composite material containing ultra-fine potassium titanate fibers to make 3D printing more practical

This 3D printer filament features high dimensional accuracy and precision moldability and is capable of molding functional parts such as robots. It is a filament material that meets the needs of 3D printer users, enabling the modeling of actual parts such as process transfer trays, gears for reduction gears, and mechanical parts, in addition to prototypes and production jigs.

Solution

Filament material for thermal melting and laminating (MEX) method 3D printers, which is composed of ultra-fine potassium titanate fibers blended with thermoplastic resin

This is a filament material for thermal melting and stacking (MEX) 3D printers. It is also capable of molding minute parts and has excellent sliding properties.

Features

- High precision moldability

- High dimensional accuracy

- Excellent surface smoothness

- Good sliding properties

- Low nozzle aggressiveness

Physical Properties

Poticon Filament NTL34M

| physical properties | Evaluation Method | physical property | |||

|---|---|---|---|---|---|

| Physical and Chemical Properties | tints | visual inspection | white | ||

| Filament diameter (mm) | Laser Displacement Transducer | 1.75 ± 0.05 | |||

| Intense heat loss (wt%) | 120℃ × 1h | < 1.0 | |||

| Glass Transition Temperature(TG) (℃) | ISO3146 | 60 | |||

| Density (g/cm³) | ISO1183 | 1.27 | |||

| Mechanical strength(4)(5) | Forming direction | X-Y direction | Z-X direction | ||

| Tension strength (MPa) | ISO527-1 | 114 | 68 | ||

| Tensile elongation (%) | ISO527-1 | 4.1 | 4.8 | ||

| Tensile Modulus (GPa) | ISO527-1 | 5.6 | 2.7 | ||

| Bending strength (MPa) | ISO178 | 199 | 107 | ||

| Flexural Modulus (GPa) | ISO178 | 7.0 | 2.8 | ||

| IZOD Impact Strength (Notched) | ISO179 | 32 | 40.5 | ||

| Hot Properties(4)(5) | Deflection temperature under load | 0.45 MPa (℃) | ISO 75 | 129.9 | 125.7 |

| 1.80 MPa (℃) | 104.8 | 75.0 | |||

(4) Specimens were formed by Gutenberg G-ZERO with a 0.4mm nozzle.

(5) Physical properties are representative values and are not guaranteed.

Poticon Filament NTL34MB

| physical properties | Evaluation Method | physical property | |||

|---|---|---|---|---|---|

| Physical and Chemical Properties | tint | visual inspection | black | ||

| Filament diameter (mm) | Laser Displacement Transducer | 1.75 ± 0.05 | |||

| Intense heat loss (wt%) | 120℃ × 1h | < 1.0 | |||

| Glass Transition Temperature(TG) (℃) | ISO3146 | 60 | |||

| Density (g/cm³) | ISO1183 | 1.27 | |||

| Mechanical strength(4)(5) | Forming direction | X-Y direction | Z-X direction | ||

| Tensile strength (MPa) | ISO527-1 | 115 | 68 | ||

| Tensile elongation (%) | ISO527-1 | 4.1 | 4.9 | ||

| Tensile Modulus (GPa) | ISO527-1 | 5.7 | 3.1 | ||

| Bending strength (MPa) | ISO178 | 184 | 112 | ||

| Flexural Modulus (GPa) | ISO178 | 6.7 | 2.9 | ||

| IZOD Impact Strength (Notched) (J/m) | ISO179 | 32.8 | 50.0 | ||

| Hot Properties(4)(5) | Deflection temperature under load | 0.45 MPa (℃) | ISO 75 | 152.0 | 127.8 |

| 1.80 MPa (℃) | 126.6 | 76.6 | |||

(4) Specimens were formed by Gutenberg G-ZERO with a 0.4mm nozzle.

(5) Physical properties are representative values and are not guaranteed.

Poticon Filament NTL36

| physical properties | Evaluation Method | physical property | |||

|---|---|---|---|---|---|

| Physical and Chemical Properties | tints | visual inspection | white | ||

| Filament diameter (mm) | Laser Displacement Transducer | 1.75 ± 0.05 | |||

| Intense heat loss (wt%) | 120℃ × 1h | < 1.0 | |||

| Glass Transition Temperature(TG) (℃) | ISO3146 | 60 | |||

| Density (g/cm³) | ISO1183 | 1.40 | |||

| Mechanical strength(4)(5) | Forming direction | X-Y direction | Z-X direction | ||

| Tensile strength (MPa) | ISO527-1 | 145 | 67 | ||

| Tensile elongation (%) | ISO527-1 | 3.7 | 2.6 | ||

| Tensile Modulus (GPa) | ISO527-1 | 8.2 | 3.3 | ||

| Bending strength (MPa) | ISO178 | 245 | 110 | ||

| Flexural Modulus (GPa) | ISO178 | 9.7 | 3.2 | ||

| IZOD Impact Strength (Notched) (J/m) | ISO179 | 28.6 | 27.4 | ||

| Hot Properties | Deflection temperature under load | 0.45 MPa (℃) | ISO 75 | 139.2 | 127.9 |

| 1.80 MPa (℃) | 109.5 | 82.4 | |||

(4) Specimens were formed by Gutenberg G-ZERO with a 0.4mm nozzle.

(5) Physical properties are representative values and are not guaranteed.

Poticon Filament RT4

| physical properties | Evaluation Method | physical property | |||

|---|---|---|---|---|---|

| Physical and Chemical Properties | tint | visual inspection | white | ||

| Filament diameter (mm) | Laser Displacement Transducer | 1.75 ± 0.05 | |||

| Intense heat loss (wt%) | 120℃ × 1h | < 1.0 | |||

| Glass Transition Temperature(TG) (℃) | ISO3146 | 89 | |||

| Density (g/cm³) | ISO1183 | 1.51 | |||

| Mechanical strength(2)(3) | Tensile strength (MPa) | ISO527-1 | 110 | ||

| Tensile elongation (%) | ISO527-1 | 2.8 | |||

| 引張弾性率 (GPa) | ISO527-1 | 7.2 | |||

| Bending strength (MPa) | ISO178 | 210 | |||

| Flexural Modulus (GPa) | ISO178 | 9.7 | |||

| IZOD Impact Strength (Notched) (J/m) | ISO179 | 31.3 | |||

| Hot Properties(2)(3) | Deflection temperature under load | 0.45 MPa (℃) | ISO 75 | 266.8 | |

| 1.80 MPa (℃) | 231.9 | ||||

(2) Specimens were formed by Gutenberg G-ZERO, using a 0.4mm nozzle, in the X-Y direction.

(3) Physical properties are representative values and are not guaranteed.

Purpose

Robot parts (mechanical parts, gears, bearings)

Robots parts, Gear, Decelarator, Jig

Track Record

Quadruped Robot

This is a production example of a quadruped robot that actually works by modelling mechanical parts and gears with a 3D printer using Poticon filament. (*Co-operation from Endo Laboratory, Tokyo Institute of Technology)

Drink-Serving Robot

This is an example of a drink serving robot made with a 3D printer using Poticon filament. All the mechanical parts and reduction gears were formed using a 3D printer, and the robot operates in a stable manner. (*Co-operation from Irie Laboratory, Department of Precision Engineering, Nihon University)