Blowing agent preventing solidification, agglomeration and dust formation

Uniform AZ Ultra is a blowing agent preventing solidification, agglomeration and dust formation. It is based on powder technology and developed using Otsuka Chemical’s original surface treatment technology. While retaining the characteristics of Uniform AZ, it also prevents solidification and dust formation.

Solution

It can help enhance a foam product’s quality and improve the work environment.

Uniform AZ Ultra also enhances dispersibility within a resin through surface treatment and contributes to greater usability (management of products in stock, improvement of weighing and injection operations) by preventing solidification and dust formation.

Advantages

- Superior compatibility and dispersibility in plastics, rubber, etc.

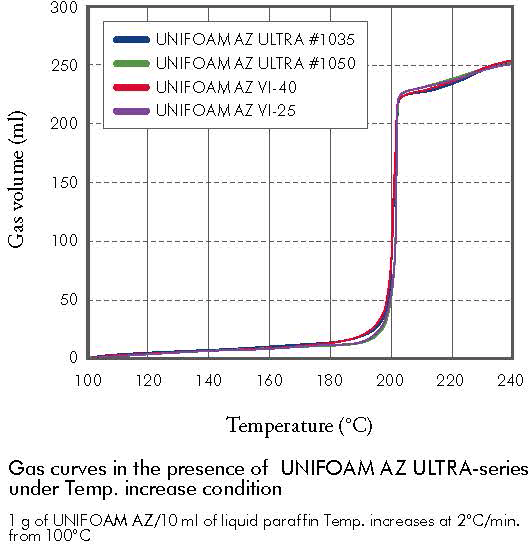

- Decomposition temperatures suitable for plastic and rubber processing

- Ability to control decomposition temperature and speed

- Large gas volume (220-245ml/g)

- Low amount of contamination from degradation

- Low degradation over time; excellent storage stability

- No moisture absorption during storage, easy to warehouse

- Dry grade allows for air shipment and automatic weighing

- Dust prevention improves working environment

- Enhanced dispersion in the resin; reduces voids and pinholes

The solidification prevention example and Dust prevention example

General Properties

Basic grades of “UNIFOAM AZ ULTRA-series”

| Grade | Unit | #1195-I | #1100-I | #1067-I | #1050-I | #1035-I |

|---|---|---|---|---|---|---|

| Appearance | Yellow fine powder | Yellow fine powder | Yellow fine powder | Yellow fine powder | Yellow fine powder | |

| Median Particle Size | μm | 17.5±3.5 | 9.0±1.5 | 6.5±1.3 | 5.0±1.0 | 3.2±0.7 |

| Decomposition Temp. | °C | 201±2 | 200±1 | 200±1 | 200±1 | 200±1 |

| Volatile Matter | % | <=0.2 | <=0.2 | <=0.2 | <=0.2 | <=0.2 |

| Gas Collected (20°C, 1atm) | ml/g | >=230 | 240±5 | 240±5 | 240±5 | 240±5 |

Applications

- Energy absorption, elastic functionality(cushioning)

- Sound absorption, automotive interiors

- Mechanical functionality( elasticity, flexibility)

- Light-weight applications

- Decorative( wallpaper, leather)

- Thermal( heat insulation)

Achievements

Wallpaper, flooring, insulation, leather, etc.