On September 12, 2025, Otsuka Chemical Co., Ltd. (Head Office: 3-2-27 Otedori, Chuo-ku, Osaka-shi; President and Representative Director: Hiroyoshi Tosa; hereinafter “Otsuka Chemical”) has acquired new technology and begun construction of a new plant to expand production capabilities, looking towards fundamental enhancement of the functional polymer business.

Otsuka Chemical and Kuraray Co., Ltd. (Head Office: Tokiwabashi Tower, 2-6-4 Otemachi, Chiyoda-ku, Tokyo; President and Representative Director: Hitoshi Kawahara; hereinafter “Kuraray”) have reached an agreement for Kuraray to transfer a portion of its IP rights related to KURARITY™ acrylic block copolymer to Otsuka Chemical, as well as for Kuraray to provide assistance in Otsuka Chemical’s introduction of the product’s manufacturing technology.

The newly introduced technology is Kuraray’s living anionic polymerization technology, related to its independently developed product KURARITY™, a long-standing product of the company. This technology involves a unique catalyst system that enables production of polymers with an extremely narrow molecular weight distribution and high purity. This acrylic material has excellent clarity and can assume a wide range of forms, from soft to rigid, with potential for applications in various modifiers, additives, adhesives, and molding compounds.

Meanwhile, Otsuka Chemical has also long offered TERPLUS, a functional polymer synthesized by its originally developed living radical polymerization method (TERP method). Similar to KURARITY™, TERPLUS is an acrylic controlled polymer, but it demonstrates distinct properties and functionalities. With the introduction of Kuraray’s technology, Otsuka Chemical will own two controlled polymerization methods: living anionic polymerization and living radical polymerization. The two technologies combined will allow us to propose unprecedented high-performance polymers tailored to customer needs.

Moving forward, Otsuka Chemical will prepare to supply alternative products to customers of KURARITY™, while aiming to provide innovative solutions that address customer needs—particularly in fields requiring advanced technologies, such as semiconductors, electronics, and healthcare—through the development of new grades. Our goal is to work together with Kuraray to create next-generation products.

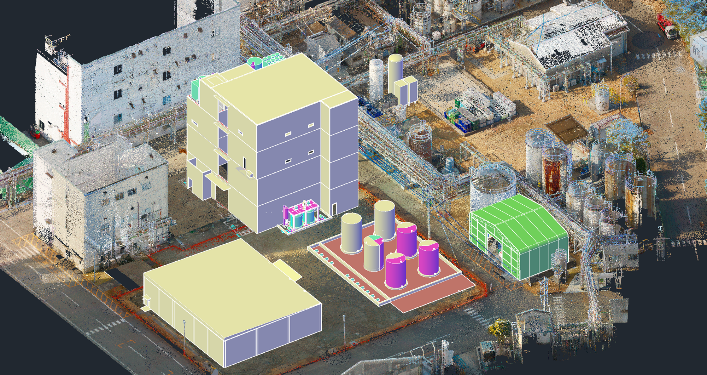

Until now, Otsuka Chemical has produced TERPLUS within the first TERPLUS plant established in 2014, and the product has recorded significant growth as an LCD color filter pigment dispersant. As demand continues to grow for dispersants in inkjet printing inks—a field expected to expand globally—and with projected demand for new hollow fiber membranes in the purification of biopharmaceutical active pharmaceutical ingredients, Otsuka Chemical has decided to build a second plant within its Tokushima Factory site.

Scheduled to launch operations in 2027, this second plant will be designed to meet diverse needs, enabling the production of water-based polymers in addition to conventional organic solvent-based polymers. The new multifunctional, versatile plant will be equipped to meet the increasing demand for environmentally friendly applications, including water-based paints and inks.

[Otsuka Chemical Tokushima Factory, TERPLUS Second Plant]

[Overview of New Plant]

Building: 4 above-ground floors, total floor area approximately 1,546.88 m²

Start of operations: May 2027

Otsuka Chemical has succeeded in adding a greater variety of multifunctional technologies by expanding to two types of living polymerization techniques. We will continue developing and supplying customized products closely tailored to customer demands. These high-performance, high value-added polymers will enable us to offer functionalities unattainable by other companies, aligned with our customers’ needs. Otsuka Chemical is committed to striving to be a company that transforms our materials to KATACHI or parts through the ‘power of materials’ and contributing society through our unique chemical products.

[Reference Information]

■ TERPLUS: A functional polymer synthesized by Otsuka Chemical’s originally developed TERP method (a type of living radical polymerization method). Its highly precise controlled block polymer structure realizes high performance unattained by traditional polymers.

■ KURARITY™: An acrylic block copolymer developed by Kuraray Co., Ltd. Produced with Kuraray’s original catalyst system-driven living anionic polymerization technology, these polymers feature an extremely narrow molecular weight distribution and excellent purity.

For inquiries related to this initiative, contact:

General Affairs Department,

Otsuka Chemical Co., Ltd.

Occ.Release@otsuka.jp