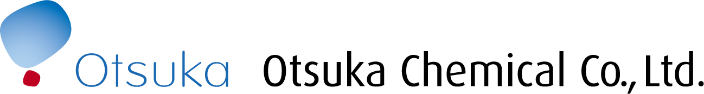

Process development

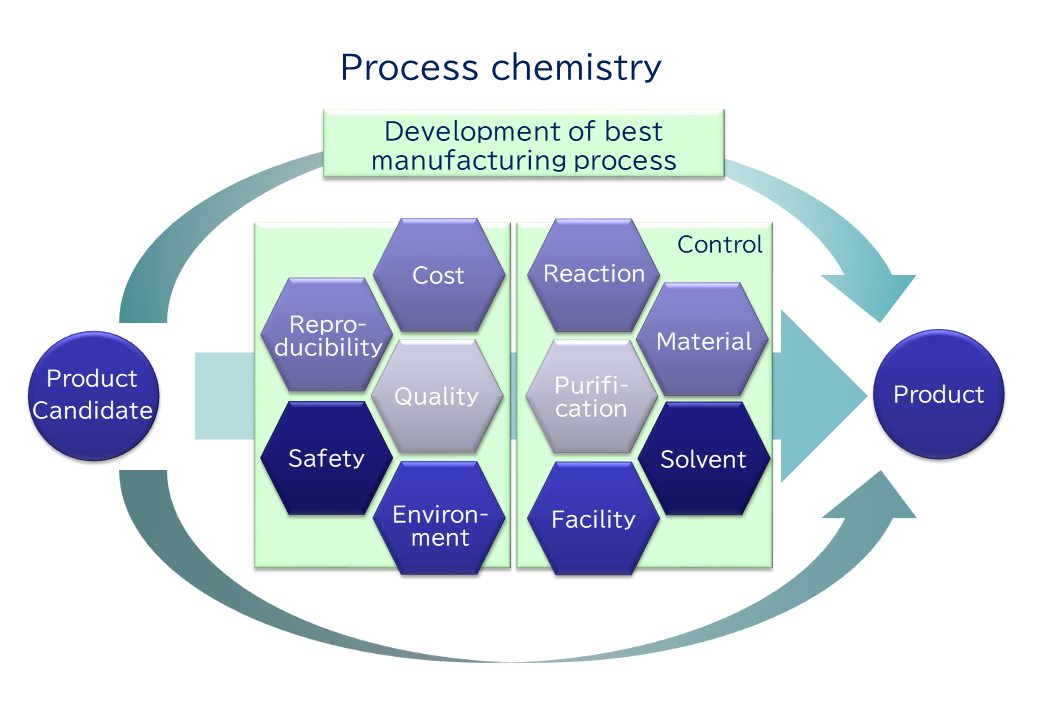

The Technology Development Laboratory is working to support stable production, to improve product appeal and to develop processes for future products. It uses process development technologies that it has cultivated over many years to create a wide variety of products such as hydrazine derivatives, beta-lactam compounds and other fine chemicals.

Features of the research institute

-

From initial studies to the opening of plants

Its scope of research includes the exploration of formulae for projects in the early stages of development, prototyping and the opening plants for many different kinds of compounds. We develop chemicals independently and we are commissioned to produce chemicals. The unique technologies possessed by this laboratory include technologies for handling hydrazine, derivatization technologies, technologies for beta-lactam intermediates and technologies for the customized synthesis of APIs.

Development case studies

-

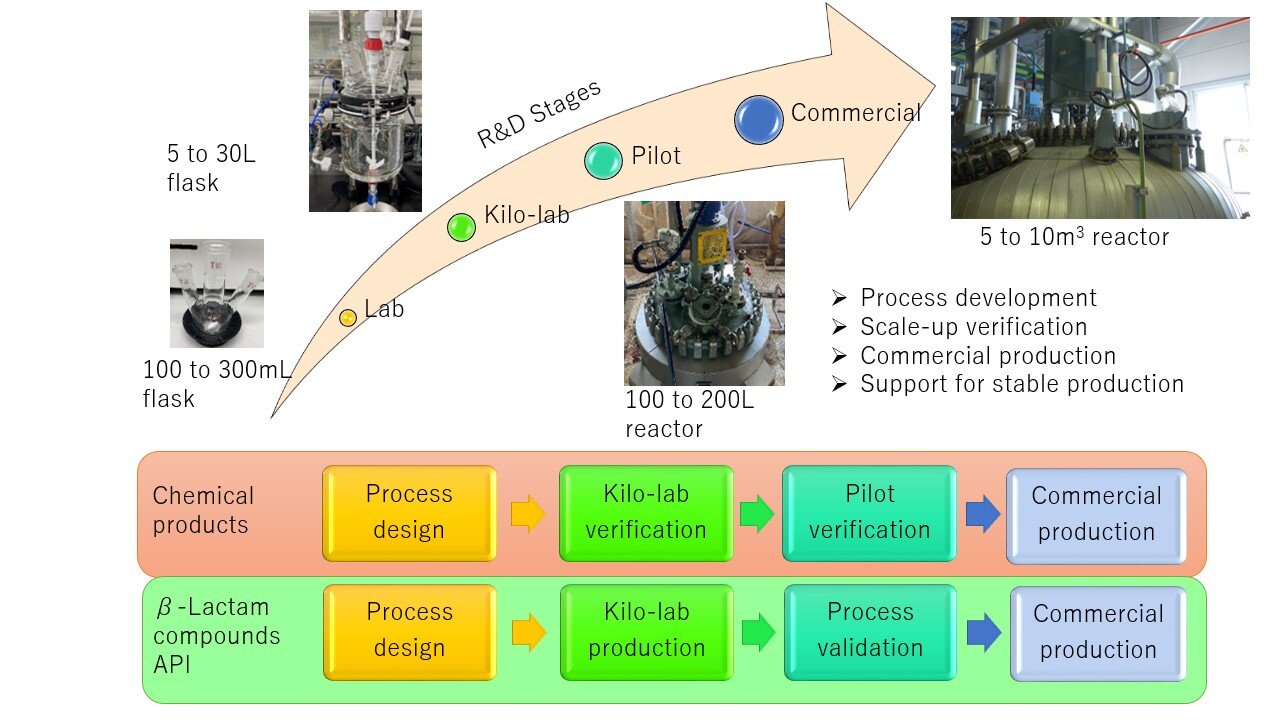

Technologies for derivatizing hydrazine

We became the first in Japan to successfully industrialize hydrazine monohydrate and other hydrazine derivatives. Additionally, the laboratory researches manufacturing processes and the commercialization of foaming agents, azo polymerization initiators, ultraviolet absorbing agents, rust preventive agents, electrolytes for capacitors and other items. We are engaged in extensive research and development activities including the custom synthesis of different derivatives to suit customer needs.

-

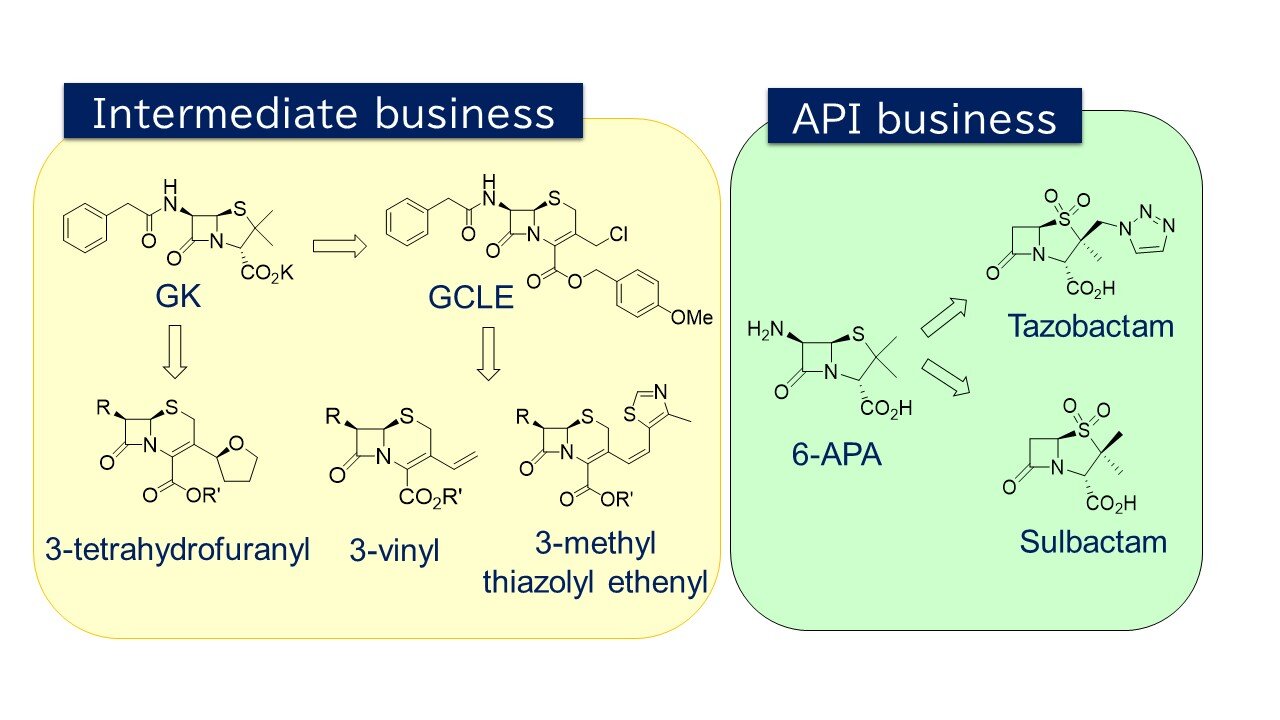

Technologies for synthesizing beta-lactam intermediates and APIs

The laboratory develops formulae for different developed compounds, APIs and intermediates and verifies the scaling up of processes based on the technologies accumulated in the development of tazobactam, a beta-lactamase inhibitor, and GCLE, a key cephalosporin intermediate for pharmaceutical applications. Thus, we have a structure that enables us to fulfill customers' requests.

-

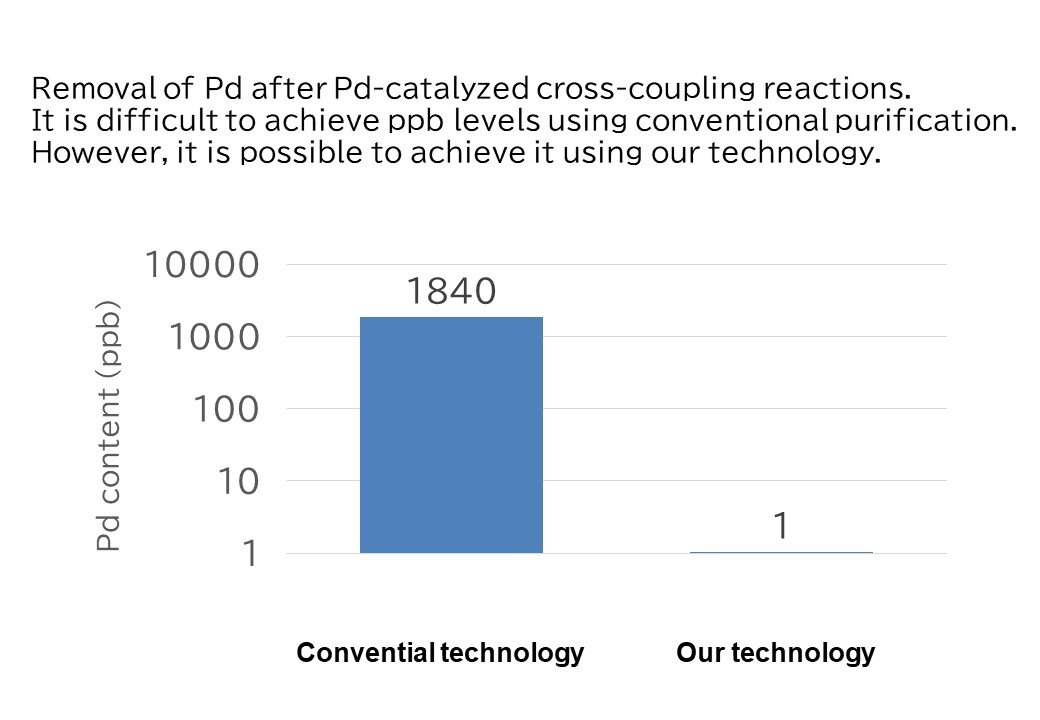

Technologies for manufacturing high-purity products

The laboratory researches and develops technologies for manufacturing the high purity products required for metal reductants, resists, chemical mechanical polishing (CMP) slurries and other additives for semiconductors and raw materials and intermediates for pharmaceuticals. We will fulfill needs for products and the commissioned manufacturing of highly refined products, handling everything from metallic impurities to organic impurities.