Research into functional polymers using living radical polymerization

Radical polymerization is extensively used in the industrial production of polymers because of its versatility in the polymerization of many vinyl monomers under mild conditions.

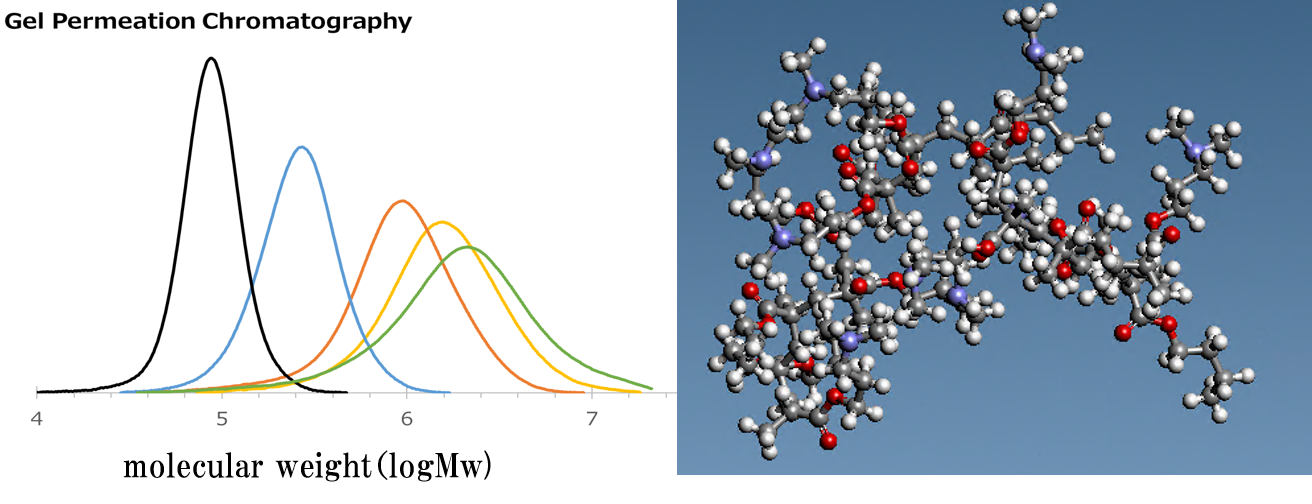

Living radical polymerization is a polymerization method in which the molecular weight, molecular weight distribution and structure of the polymers generated can be precisely controlled utilizing the versatility of the radical reaction.

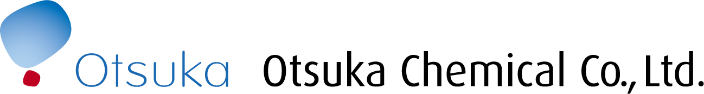

The Advanced Polymer Laboratory has worked with a group led by Kyoto University professor Shigeru Yamago on research and development focused on the uses of organotellurium-mediated living radical polymerization (TERP).

TERPLUS, a group of functional polymer products synthesized using TERP, have been commercialized for use in pigment dispersants and adhesives.

TERP is a suitable production method for industrial functional polymer materials due to the wide range of monomer types and reaction solvents that can be used and the controllable molecular weight range. We are pursuing the development of new and broader ranging applications for TERPLUS.

Features of the research institute

-

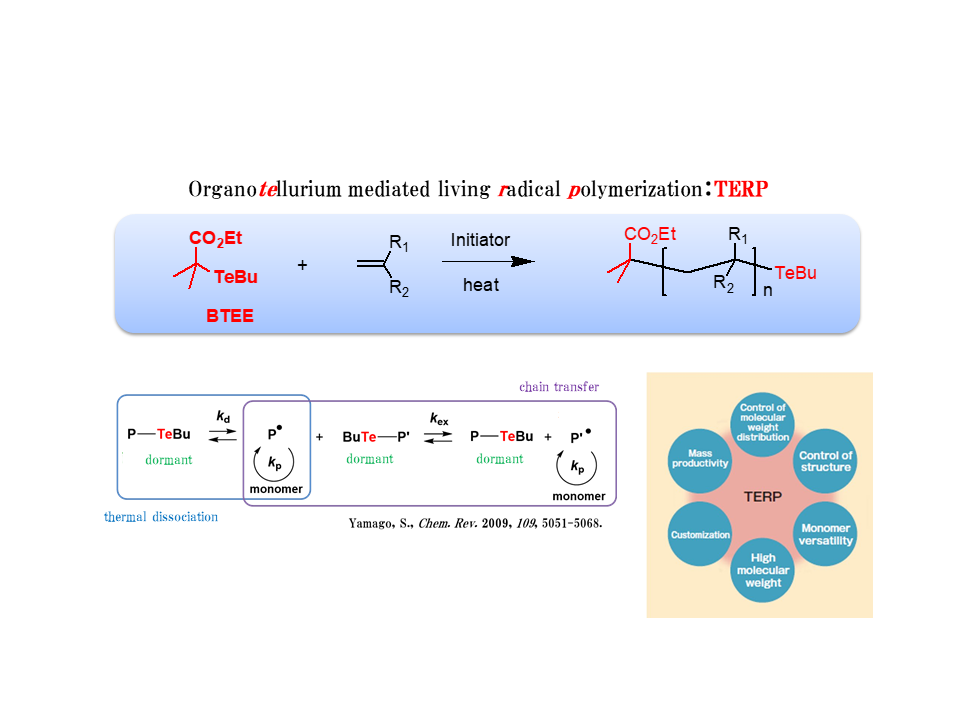

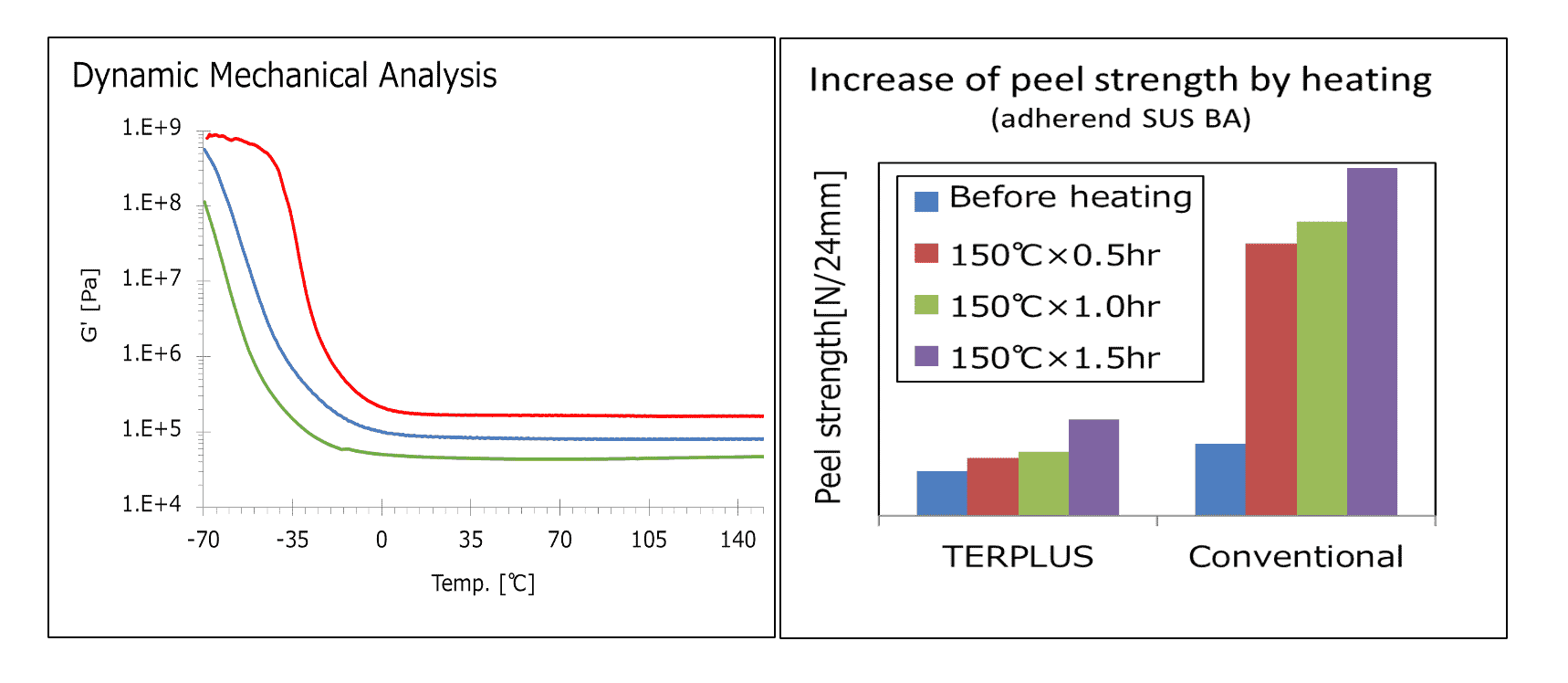

Applied research into uniform network structures

Using TERP, you can synthesize a crosslinked polymer with a uniform network structure by post-crosslinking macromolecules using controlled molecular weight distribution.These crosslinked polymers can be highly cohesive, thermally durable and elastic and have other properties.The Advanced Polymer Laboratory utilizes these characteristics to develop many different utilizations.

-

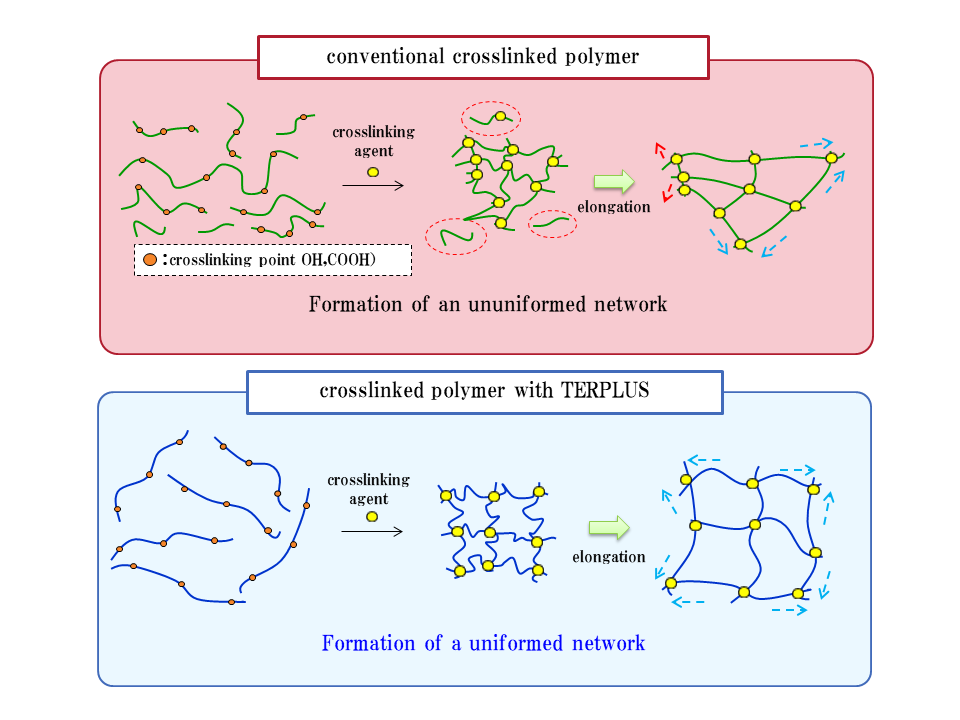

Applied polymeric micelle morphology research

We conduct research into polymeric micelles utilizing the high degree of freedom that TERP makes possible in the design of block copolymers.By precisely designing the molecular weight and composition of block copolymers it is possible to control the shape of micelles when added to a matrix resin.

-

Research into the functionalization of block copolymers

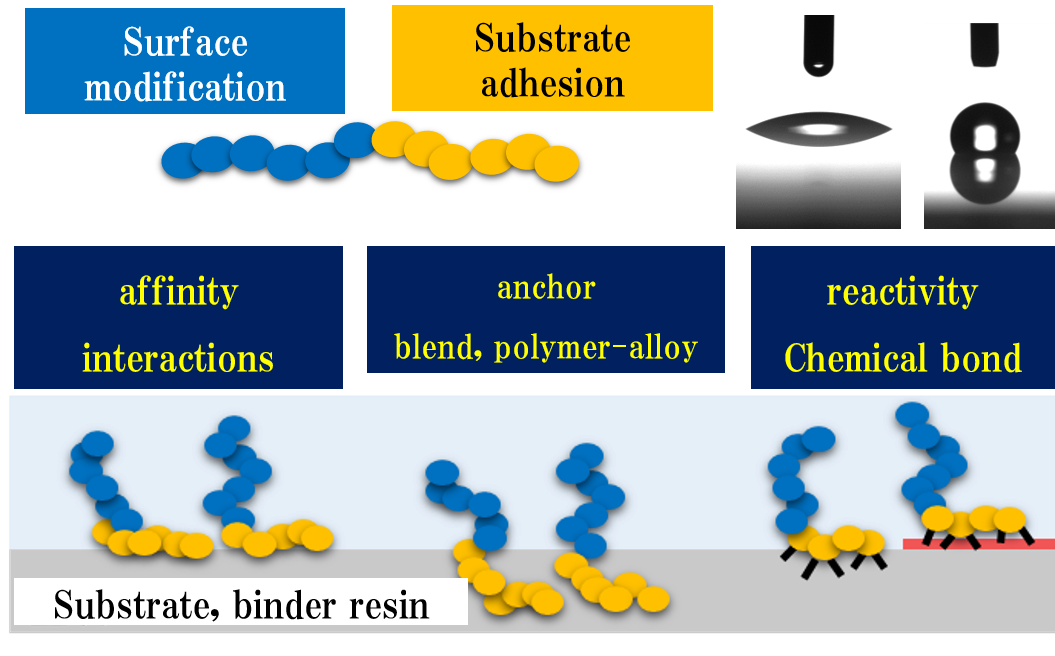

We research the functionalization of block copolymers leveraging the high degree of freedom that TERP makes possible in the design of block copolymers.An example of this is a film whose base material has been coated with AB block copolymers. These include A segments which modify the surface and B segments which enable base material cohesion. This film can modify a surface to improve the wettability of the base material and increase stability.We optimize the function and structure of block copolymers depending on their usage.

-

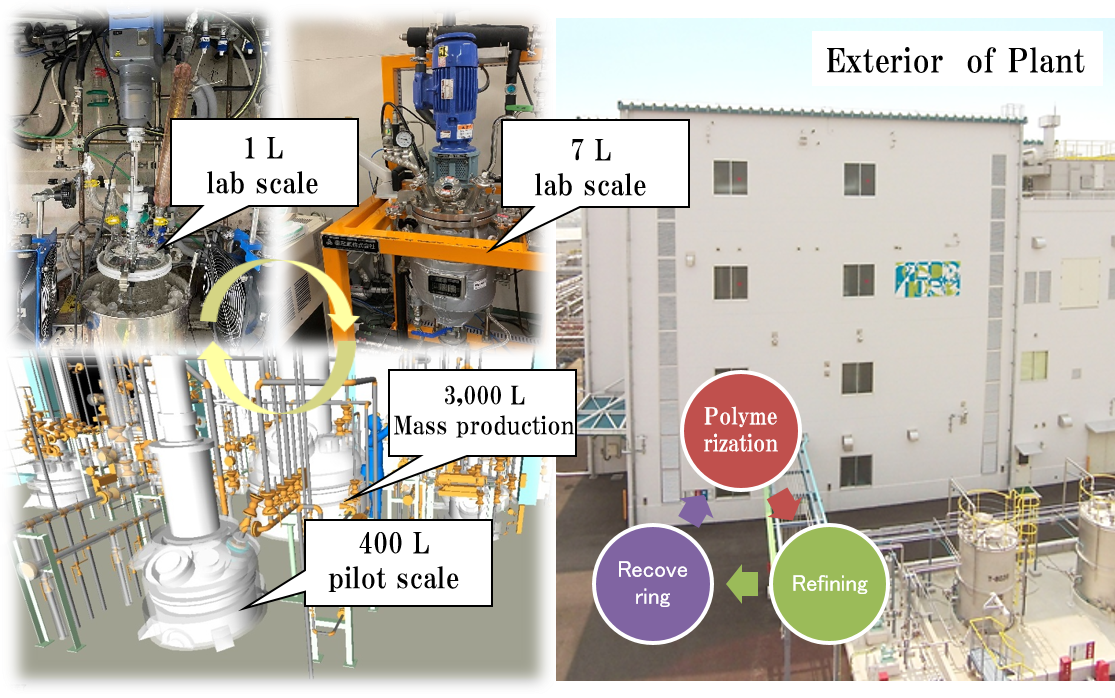

Development of processes for industrialization

The Advanced Polymer Laboratory also develops processes for the industrial production of TERPLUS.Our TERP plant handles the entire process from polymerization and generation to the recovery and recycling of organotellurium compounds.We pursue the smooth shift to mass production by accumulating and examining data using the polymerization equipment we have in our lab on a multi-scale basis.

Development case studies

-

Digital transformation (DX) in research

TERP can be used to create macromolecules with narrow and precise molecular weight distribution.Precise data about properties such as polymer chain entanglement can be obtained from macromolecules whose molecular weight is controlled. This data can be analyzed using AI and machine learning.We utilize DX in research to accelerate the functionalization of TERPLUS and the development of applications for it.

-

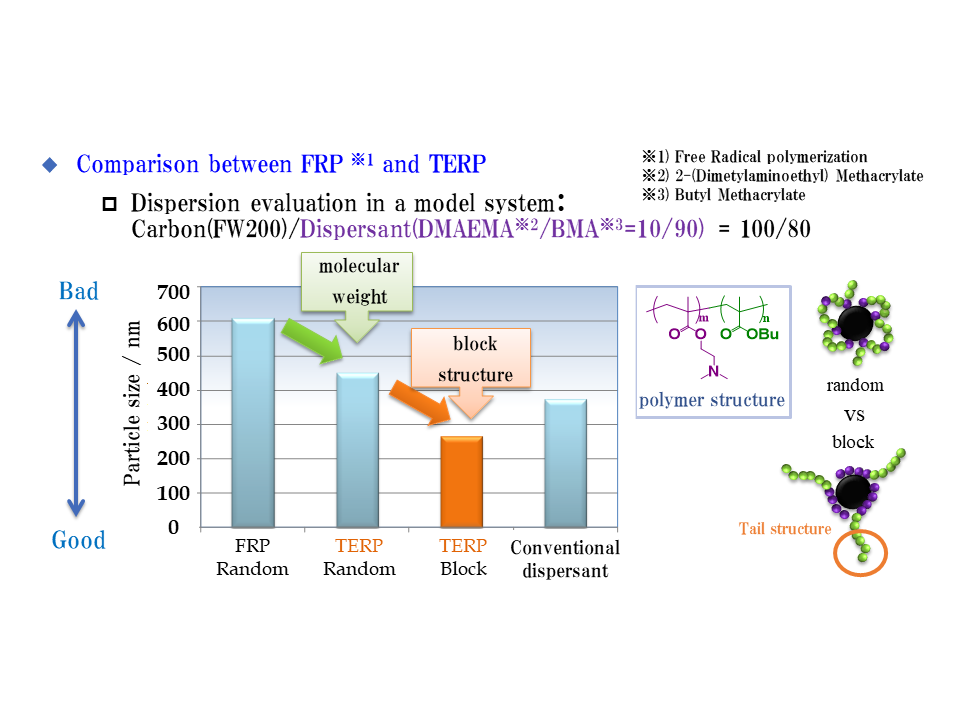

Development of pigment dispersants

We develop and launch pigment dispersants using monomer polymerization control with polar functional groups and the high degree of freedom in the design of block copolymers that is characteristic of TERP.Block structures that can have their tail structures removed when they are adsorbed into a pigment can act as dispersants.

-

Development of adhesives

In the area of high molecular weight products, we develop and launch adhesives leveraging the characteristics of TERP which enables molecular weight and molecular weight distribution to be highly controlled.Adhesives with a uniform network structure retain thermal durability by maintaining their elastic modulus up into high temperature zones.