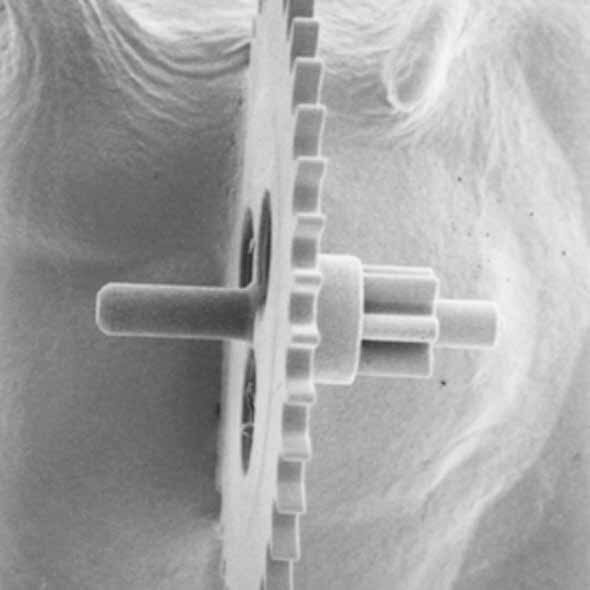

POTICON: A composite material containing TISMO ultrafine potassium titanate fiber

POTICON is a thermoplastic material that is able to fulfill a range of customer needs. POTICON has many applications. It can be used in products ranging from LED reflector components, camera module components and other products where micro-reinforcement properties are required to automotive bearing components and other products where high strength and high sliding properties are required.

Solution

Potassium titanate fiber added to the thermoplastic resin as a fine filler reinforces ultrafine parts and results in superior dimensional stability. It is not aggressive on the materials on which it slides, opening the path to grease-free products. Damage to molding machines and metal molds is minor, and it is highly recyclable, making it useful in cost-reduction activities.

Advantages

1.Micro-reinforcement

Fibers are dispersed uniformly in micrometer order in the plastic. This paves the way for ultra-precision molding and low thickness molding.

The development of superior friction and wear properties and sliding grades of product makes it possible to mold sliding parts with outstanding friction and wear properties that don't require lubrication.

2.Highly recyclable

The rigidity, strength and size of TISMO are three features which makes it easier to recycle.

3.Outstanding dimensional precision and stability

TISMO is a very fine fiber. Its fiber orientation is relatively uniform inside injection molded products, so its use results in outstanding dimensional precision and stability.

4.Extreme surface smoothness

Products molded from TISMO-blended POTICON exhibit high mold printability which helps produce mirror-like smooth surfaces.

5.High mold workability

POTICON can be molded in the same conditions used for molding glass fiber (GF) reinforced plastics. The surface hardness of potassium titanate fiber is so low and its size is so fine that it can result in less wear on metal molds and molding machines than would be caused by GF reinforced plastics, which can help reduce total cost.

General Properties

| Polymer | POM | PBT | PA | MXD6PA | PC | PPS | LCP | PEEK | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Grade | OA30 | BT262 | NTE264 | NT363 | CT26B | RBA514 | VT6 | KT16 | ||

| Unit | Test method | |||||||||

| Specific gravity | D792 | 1.68 | 1.58 | 1.38 | 1.48 | 1.51 | 1.6 | 1.69 | 1.58 | |

| Water absorption rate | % | D570 | 0.2 | 0.07 | 1 | 0.2 | 0.11 | 0.02 | 0.08 | 0.02 |

| Tensile strength | MPa | D638 | 111 | 102 | 119 | 150 | 104 | 78 | 235 | 116 |

| Elongation at break | % | D638 | 3.5 | 3.2 | 3.7 | 3.1 | 5 | 2.2 | 6.3 | 4.4 |

| Flexural strength | MPa | D790 | 169 | 158 | 177 | 238 | 166 | 120 | 212 | 248 |

| Flexural modulus | GPa | D790 | 8.8 | 8.3 | 7.5 | 11.2 | 7.6 | 7.1 | 13.7 | 9.9 |

| Izod impact strength | J/m (notched) | D256 | 44 | 49 | 39 | 31 | 41 | 25 | 245 | 45 |

| J/m | D256 | 637 | 794 | 774 | 627 | - | 127 | - | - | |

| Coefficient of kinetic friction | *Otsuka method | 0.28 | 0.19 | 0.15 | 0.14 | - | 0.2 | 0.37 | - | |

| Specific abrasion volume | X10-1mm3 /N・km |

0.296 | 0.012 | 0.006 | 0.018 | - | 0.021 | 0.143 | - | |

| Specific abrasion of counterpart | X10-1mm3 /N・km |

0 | 0 | 0 | 0 | - | 0 | 0 | - | |

*Otsuka method : This Size is measured size of 90×50×3 mm molded item by vernier caliper

Applications

-

Automotive Parts(gears, bearings)

-

LED Reflectors

-

Watch Parts(gears, ground plane)

-

Camera(image stabilization parts)

-

Sliding Parts(gears, wheel bearing)

-

Camera Module Parts

-

Motor Parts(cog-wheels, bearings)